Cuyahoga Falls, OH (May 2019) – Becker Pumps Corporation is launching a defensive strategy to combat the flood of low-priced Chinese imports posing as OEM replacement parts for Becker pumps and compressors. Becker is employing an extensive customer education program and launched an e-commerce site restricting the sale of genuine Becker parts through a new online store.

Counterfeit parts have become a big problem for US companies. U.S. manufacturers are not only losing sales and market share but poor performance and premature failures can negatively impact the manufacturer’s brand. Becker’s solution is a customer education program focusing on how to identify counterfeit, non-OEM parts and the associated performance problems. Becker also launched an online store to give clients easy access to Becker Genuine parts only available through the store.

Over the past 130 years, Becker has perfected the design and manufacturing of a complete line of oil-flooded pumps, oil-free rotary vane pumps, regenerative blowers, and low-pressure compressors. The internal components of their pumps and compressors are high-tolerance and with proprietary carbon chemistry, binding resins and hardening processes. Becker Genuine parts are specifically engineered for the operating characteristics of a Becker pump.

The most expensive replacement parts are the carbon vanes used in Becker’s oil-less rotary vane pumps and knock-off parts have appeared across the internet. Websites show a picture of the Becker part with logo and packaging then when the customer clicks on the part it is switched to their low-cost off-brand part. Deceptive language describing the part makes it unclear that the customer is not ordering an OEM part.

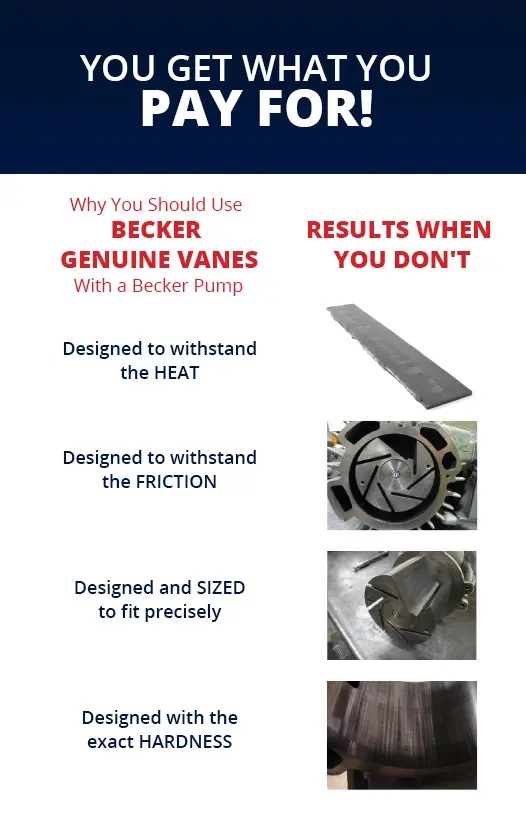

Becker Genuine vanes are wear components; they are engineered to withstand the heat caused by friction with the longest possible life and consistent performance. This means maintaining vacuum pressure throughout the life of the vane. At the end of life, they are designed to fail in a way that does not damage the pump. The imposter sites claim to have the same engineered quality as Becker Genuine carbon vanes. Becker has performed extensive testing of the off-brand vanes. These vanes lose significant vacuum pressure and wear 2-3 times faster. The vanes prematurely cup, chip and break resulting in immediate loss of pressure. They also result in catastrophic pump failure. When they fail, the off-brand vanes shatter and seize the pump causing permanent damage.

As Managing Director of Becker Pumps USA, Jason Rathbun recently stated “A lot of people don’t know that most of these cheap imitation vanes are made in China, and we see the results of using them every day. When a customer tries to cut corners by using cheap vanes, the pump ends up in our repair department for a complete rebuild. Trust me, that does not save the customer money, especially since that voids the warranty. If we can get our message out about the long term cost savings of buying our specifically engineered Becker Genuine vanes, we feel we have done our customers a service to improve the longevity of their oil-free pumps.”

Darin Ladd, National Sales Manager for Becker Pumps added, “We at Becker pride ourselves in knowing that we manufacture products to the highest standards and have for more than 130 years. Customers think they are saving a couple of bucks when they purchase cheap carbon vanes. But when the pump fails, how much does that really cost. Forget the cost of the repair of that pump or even the cost of a new pump. The customer has to consider the cost of lost production when their production line isn’t running. That’s a huge dollar figure no one wants to talk about. Are they really saving money buying cheap vanes? ”

For additional information on the entire line of Becker pumps and our new online shop, visit www.beckerpumps.com or contact: Jason Rathbun by phone at 330-928-9966, Becker Pumps Corporation, 100 E. Ascot Lane, Cuyahoga Falls, Ohio, 44223-3768.