Screw Compressors

![]()

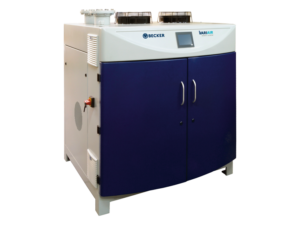

Becker’s screw compressors are dry positive-displacement pumps. They have two counter-rotating rotors and a housing that encloses the rotors. Thanks to the direct drive via an integrated frequency inverter, a drive gear is no longer required.

The rotors are designed with a regular, thread-shaped profile and mesh with each other like cogwheels. When the rotors rotate, they move out in a machine direction and convey the medium from the suction side (inlet) to the pressure side (outlet). They rotate in opposite directions without touching one another or the housing.

The working chamber of the machines is 100% oil-free, making them relatively maintenance free. The integrated speed control enables energy-optimized operation of the devices. Becker drives continuously adjust the volume flow to the demand. It‘s high efficiency results into low energy consumption.

Watch the video below to learn more about how our screw compressors work.

APPLICATION AND MARKET USES

As a leader in the field of suction and blast air, we offer complete solutions driven by your individual needs. Our screw compressors are the ideal solution for many industrial applications. Click on your market or application below to learn how Becker’s screw compressors can help your business or application.

BY APPLICATION

-

Blowing & Injecting

Compressors are used to build up pressure to supply air for the aeration of waste water, blast air for printing, wine presses, drainage system reliners, and other processes.

BY MARKET

-

General Mechanical Engineering

Becker provides customized vacuum pump and compressor solutions for numerous mechanical engineering applications across the world, such as conveying, transporting, fixing, lifting, handling, drying, cooling and many more. -

Plastics Industry

From the production of new plastic components to the resource-friendly recycling of PET – vacuum pumps/systems and compressors from Becker are involved in the process.

Information & Resources

Our Industrial Vacuum Pump Technical Guide

Becker has designed a comprehensive handbook for the use of our distributors and customers as an aid in the designing of applications involving vacuum and low pressure compressed air. Just some of what you’ll find in the complete handbook includes: Similarity of units CFM vs. SCFM vs. ACFM Motor cycling...

How to Determine the Cost of a Vacuum Pump

For manufacturers and resellers, calculating the true cost of a vacuum pump before purchasing is often a challenge. We look at the real factors that affect what you’ll pay for a new vacuum solution.

Tips for Custom Vacuum Pump Design

For many applications, a custom vacuum pump design is the best way to get a fit-for-purpose solution that improves efficiency and doesn’t compromise on features. However, the customization is only worthwhile if it meets your specific needs.

REQUEST INFORMATION

WE ARE PLEASED TO ASSIST YOU IN SERVICING YOUR BECKER PRODUCTS.

When can I expect to hear back?

Our goal is to respond to all care and employment inquiries within 24 hours of receipt. Our Becker Pumps Corporate offices are generally open Monday – Friday from 8am to 5pm EST time.