PRODUCTS

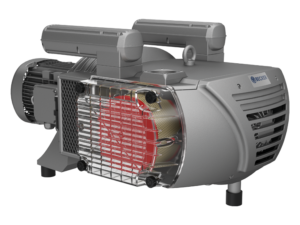

Vacuum Pumps, Compressors, Central Systems, and Original Parts from Becker

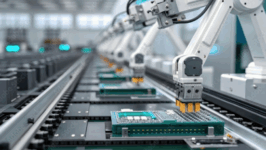

Becker provides vacuum pumps, compressors, central vacuum systems, part, accessories, and customized vacuum solutions for numerous applications in various industries around the world. With innovative solutions, a wide range of services, and years of experience, Becker solutions enhance the efficiency of plants, ensure a high level of availability and reduce maintenance costs. With more than 135 years of industry experience, even if we don’t have the product you need, we can help you find someone who does.