For many applications, a custom vacuum pump design is the best way to get a fit-for-purpose solution that improves efficiency and doesn’t compromise on features. However, the customization is only worthwhile if it meets your specific needs.

Half of a successful design comes from working with an expert pump supplier, and the other half comes from your active participation in the design process. This style of partnership minimizes wasted time and money and maximizes the value of the final unit.

The process begins with your reason for seeking a unique solution.

Why get a custom vacuum pump design?

There are numerous reasons for customizing a vacuum pump. Whatever the specifics, behind every custom design, there should be an overarching business goal. Half of a successful design comes from working with an expert pump supplier, and the other half comes from your active participation in the design process.

Here are some common motivations for engaging a custom pump supplier.

One size doesn’t fit all

Using standard parts with specialized processes makes it nearly impossible to realize the highest efficiency and functionality. When it comes to a proprietary technique or advanced process, vacuum pump components that aren’t fit-for-purpose may limit performance.

Customization lets you realize the ideal design to support superior results.

Adapt to customer demands

As technology advances, customers are demanding better performance. It’s possible to lose business to a more agile competitor if your product doesn’t exceed expectations.

A tailored approach solves complex or situation-specific requirements. For example, this CNC manufacturer partnered with Becker Pumps, creating a custom vacuum pump design as a “drop-in” solution.

Seize a competitive advantage

Using the same components as the competition makes it difficult to differentiate your products in a crowded marketplace.

Developing a fit-for-purpose, custom vacuum pump design with advanced features and capabilities helps you fulfill opportunities where others cannot, making you the vendor of choice for select applications.

Examples of Custom Vacuum Pump Design

Healthcare – central medical/surgical vacuum systems, mobile vacuum systems.

Manufacturing – forming shaped plastics, additive manufacturing.

Material handling – holding, lifting, and moving products, pick and place.

Packaging – primary, secondary, tertiary.

Woodworking – wood drying and veneering, creating suction to aid with CNC work

Typical components involved in custom design:

- Motor starters

- External inlet filters

- Check valves

- Gauges

- Sound abatement

- Receiver tanks

- Air/water (liquid) separators

Three Tips for a Successful Custom Design

Working with a vacuum pump supplier to create a custom unit is a team effort. It involves thorough consideration of the factors that go into a successful product while balancing reliability, functionality, cost, and efficiency.

Here are a few tips for developing a custom vacuum pump design.

1. Confirm performance specifics

Verifying the vacuum pump’s specifics up-front sets the stage for success. As the requester of a custom unit, you’ll want to convey your unique specifications to the supplier. This includes performance details, such as the unit’s capacity and the type of environment the pump will encounter.

Identifying the gas or vapor coming back to the pump is critical, as certain units can tolerate vapor in their chamber better than others. With particulates, like dust or wood chips, the supplier may need to consider an external filter to protect the pump from damage.

2. Know the physical limitations of your process

A custom-built unit should solve problems, not create them. Describing how you want the vacuum pump to contribute to your process will help the supplier design a unit that fits seamlessly into your existing operations.

Consider this; a lengthy pipe run leading to the vacuum pump may call for an external check valve, or space constraints may require modifications to the pump’s cover. Addressing operational realities during the design stage is far easier than making changes later.

3. Choose a supplier with a great reputation

Successful vacuum pump design has a lot to do with choosing the right pump supplier. The best suppliers have a wealth of industry experience and will listen closely and work together with you to develop a tailored design.

Ask for examples of the supplier’s previous work and talk to them about meeting your goals for the custom design. If they’re serious about custom work, they’ll be able to explain their process in detail.

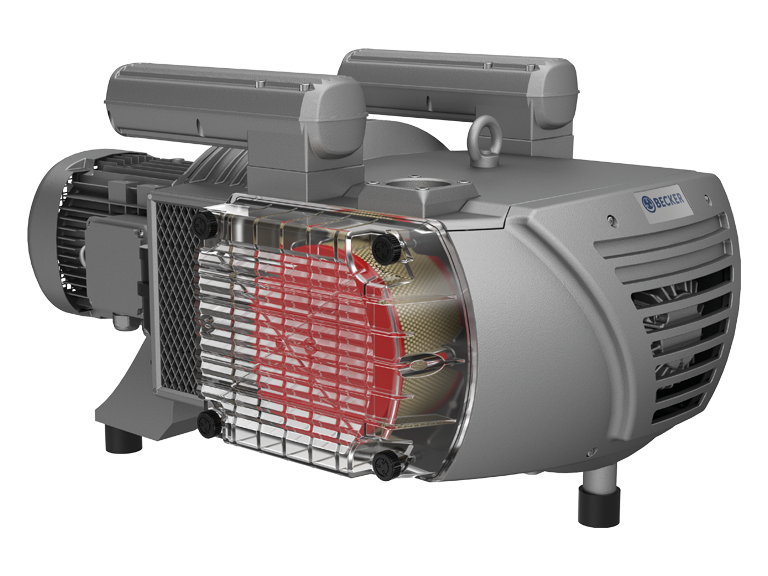

Reliable Custom Vacuum Pump Design By Becker Pumps

We’re committed to customer satisfaction. To exceed your expectations, our dedicated in-house custom design team draws on their vast experience—we’ve engineered reliable vacuum pump solutions for a range of industries.

By collaborating with expert partners within the industry, we create unique solutions that you won’t find anywhere else.