Your vacuum pump may have been running smoothly for some time, all the while producing a continuous humming sound. But what does it mean when the noise level rises? Should you be concerned?

In this post, we examine the many possible reasons for loud noises or a rattling sound coming from a vacuum pump – and what to do to fix it.

NORMAL VACUUM PUMP SOUNDS

A normal vacuum pump will have a continuous humming sound during regular operation. The sound is measured at a standard of one meter (3ft) away from the pump. At this distance, you should be able to have a normal conversation.

At Becker, the noise level of typical pumps ranges from roughly 59db-83db @ 60Hz, depending on the product. This is comparable to a vacuum cleaner or hair dryer from one meter away. The volume may vary with the pressure level.

CLICKING SOUNDS

When using a soft starter or VFD/Phase converter with soft start programming, it is normal to hear a “clicking” sound as the pump starts. For a dry vane pump, the clicking sound should decrease or go away once the pump reaches full speed.

Some of the same clicking can be heard in oil-flooded pumps until oil properly lubricates the vanes as it cycles.

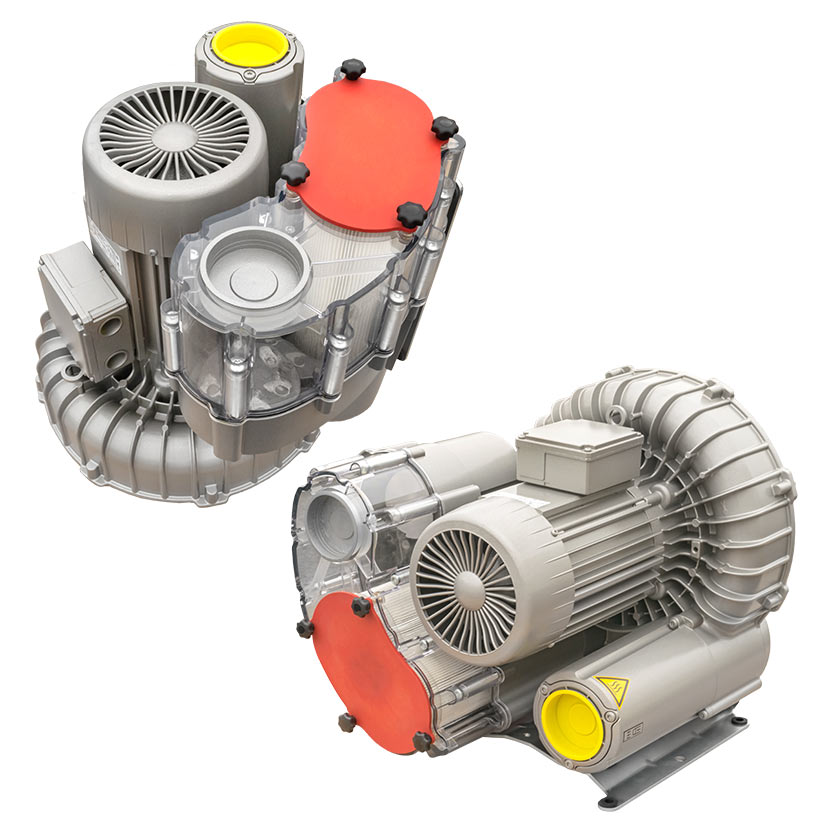

Becker SV Series single-stage regenerative blowers will start up accompanied by the roaring of air flow, which then settles down to a quiet sound in the contact-free environment.

REASONS FOR LOUD NOISE FROM A PUMP

Loud sounds coming from vacuum pump operations can be caused by a wide variety of issues, including:

- Backward rotation

- Washboarding of the housing

- Poor bearing grease quality

- Vane stuck in rotor slot

- Broken vanes

- Vacuum/Compressed air leak

- Faulty O-ring around vacuum/pressure valve

- Faulty gasket

- Metal-to-metal contact within the working chamber

- Faulty valve

- Coupling disc failure

- Cooling fan failure

- Faulty bearing

- Delaminated vanes (on lubricated pumps)

Worn vanes or damaged internal components can cause an increase in sound. After a new set of vanes is installed, allow for a break-in period of 24-48 hours when the sound level is high. Once the new vanes are seated properly, the noise will fall back to normal conditions.

Temperature issues are the leading cause of mechanical failures that can increase the sound levels.

Poor oil conditions for lubricated pumps cause the pump to work harder, which increases noise.

In general, the older the pump, the louder it becomes. After 9-10 years, the housing can become washboarded, or corrugated. This washboarding effect causes the vanes to chatter, significantly increasing sound levels.

IDENTIFY THE CAUSE

To pinpoint the cause, try to isolate the noise to a specific part of the pump. Working through the points in your pump’s maintenance guide can help determine where the sound originates, or if the sound is due to a gap in following the maintenance schedule.

Becker’s comprehensive guides outline how and when to perform maintenance tasks and show examples of damaged components. So, for example, check the vanes, filters, grease, and oil.

If the issue is deeper than just the standard maintenance points or the cause of increased noise cannot be isolated, the next step would be to call Becker’s Service Support experts.

DIAGNOSE AND FIX THE PROBLEM

Follow these steps to diagnose and potentially fix the vacuum pump noise.

For new installs, check the pump motor wiring and confirm the correct rotation. Make sure that all connections are sealed and tight.

For existing pumps, check maintenance points (bearings, oil, vane condition, etc.) and inspect housing/end shields, looking for signs of washboarding and/or signs of overheating. Inspect valve O-rings.

Washboarding is caused by age and excessive heat and typically requires repair. Metal-to-metal contact requiring replacement of any of the four major working chamber components requires professional Becker repair.

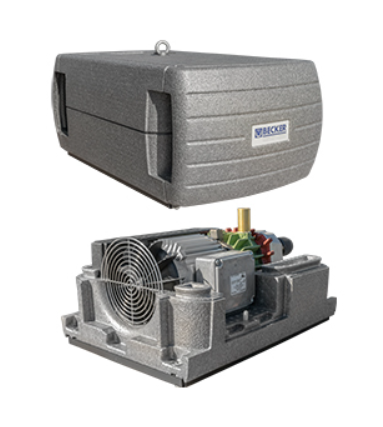

Becker allows our customers to diagnose and service their equipment more than most companies. This enables the user to be more independent when changing oil, vanes, and filters, or even inspecting the working chamber for signs of failing parts like housings, end shields, or bearings. The extent of customer repair is up to the expertise of the user. Becker’s repair team is always available when needed.

PREVENTATIVE MAINTENANCE: AVOID FUTURE NOISE ISSUES

Preventive maintenance is the best cure for almost all loud pump noise issues. Regularly inspecting/changing filters/vanes and other maintenance touchpoints will catch these problems before they become bigger, especially when it comes to noise. Rotation, and checking the bearings, filters, and vanes on schedule can all be done by the customer.

Each model has a recommended guideline for preventive maintenance. Each guide includes:

- Maintenance intervals for each task

- Tips to improve lifetime and performance

- Part numbers for maintenance kits and disposables, such as filters

Download the specific maintenance guide for your pump or reach out to your Becker contact for maintenance interval information. And when in doubt, remember: Maintenance, maintenance, maintenance!

FULL-SERVICE PUMP REPAIRS

When it comes to deciding whether to replace or repair a pump, it is very difficult to determine by noise alone. An inspection of the pump is the best way to tell, and the answer will entirely depend on the cost of the repair/overhaul versus the price of a new replacement pump.

Becker not only offers a full-service center with factory-trained technicians ready to get you back up and running, but our mobile fleet is available to help with your maintenance needs and keep you running between rebuilds. Reach out to your customer service representative for more information about your specific pump.

Becker Pumps is the leading vacuum pump expert, offering full vacuum pump service – from on-site repair to Becker factory repair, full vacuum pump rebuilds, preventative maintenance, and customer training.

Contact Becker Pumps for assistance with all your vacuum pump needs.