When deciding on replacing venturi vacuum pumps with another pump type, such as a rotary vane pump, it’s important to take into account the pros and cons of each, as well as all of the cost factors involved.

WHY REPLACE A VENTURI VACUUM PUMP WITH A ROTARY VANE PUMP?

Before replacing a vacuum pump, it’s wise to take a few moments to analyze the pros and cons of pump types to determine whether a different type of pump might serve the application better. Though Venturi pumps have become a staple for some industrial applications, rotary vane pumps are a versatile choice used in a wide range of vacuum generation applications, including additive manufacturing, food packaging, and CNC routing.

If your application needs vacuum suction for longer than a few seconds at a time, for example, you might decide to replace your existing Venturi pump with a rotary vane mechanical pump. This crossover will dramatically reduce your operating costs due to less maintenance, lower power consumption, and reduced downtime spent servicing large air compressors.

PROS AND CONS OF VENTURI PUMPS

Venturi pumps are a good choice for certain applications, including:

- Where vacuum pressure is needed only sporadically.

- In hazardous areas – Venturi pumps don’t have moving parts or electrical components which could spark an explosion.

- Where fast activation times are necessary – Venturi pumps are small and can be installed close to the process, so they can ramp up vacuum power quickly.

Machine manufacturers typically choose Venturi pumps due to their low initial investment. However, putting these pumps to work requires a much larger investment by the end customer for installing, operating, and maintaining the compressed air system needed to power the Venturi vacuum generators.

PROS AND CONS OF ROTARY VANE PUMPS

Rotary vane vacuum pumps provide higher energy efficiency, continuous availability, and lower maintenance costs than Venturi pumps. Many types of rotary vane pumps exist, designed for different industrial applications. Two basic types are oil-less rotary vane vacuum pumps and oil-lubricated rotary vacuum pumps. Each has advantages and disadvantages.

Oil-less rotary vacuum pumps are dry displacement pumps that can operate on a continuous duty basis. These require only minimal maintenance and no oil changes. Due to their construction, they can reach medium levels of vacuum.

Oil-lubricated rotary vane vacuum pumps generate deeper vacuum levels than oil-less pumps. However, this advantage is offset by greater maintenance costs, exhaust emissions, and oil disposal requirements. There’s also a possibility that the oil can become contaminated and damage the pump.

HOW MUCH CAN BE SAVED WITH A ROTARY VANE PUMP?

To determine the cost savings achievable by crossing over from a Venturi pump to a rotary vane vacuum pump, don’t be confused by the difference in the initial cost of each type of pump.

Venturi pumps themselves consist of a small cartridge that converts compressed air pressure into a vacuum. However, they require large air compressor units to power the Venturi. For example, two Venturi pumps and a 50HP air compressor might be replaced by a single rotary vane vacuum pump.

To calculate the potential cost savings of replacing a Venturi pump with a different type of vacuum pump, the following factors should be considered:

PUMP PERFORMANCE

The pump you select must be able to efficiently and effectively achieve the required vacuum at the working flow rate.

INITIAL INVESTMENT

Evaluate the initial investment required to purchase and install both vacuum generator types, including the cost of a separate compressor unit, if required.

MAINTENANCE AND SPARE PARTS AVAILABILITY

The maintenance of a direct vacuum rotary vane pump is much easier and designed to eliminate as much downtime as possible. For a Venturi system, don’t forget to include the availability and cost of spare parts for both the pump and the air compressor.

On average the annual maintenance cost of a Venturi vacuum system is 9-10% of the initial cost of the total system including the air compressor needed to generate the vacuum via a Venturi.

COST OF UTILITIES

Assess the impact on utility costs associated with operating each vacuum system option. Do not forget to include the estimated energy consumption of the air compressor system plus the Venturi generator vs. the energy consumption of a direct vacuum pump.

By switching to a direct vacuum pump, such as a rotary vane pump, the total cost of ownership including energy costs and maintenance costs is dramatically reduced. As a general rule of thumb, a customer crossing over from a Venturi pump to a rotary vane pump can expect to see savings of up to 2/3 on their utilities, depending on the application.

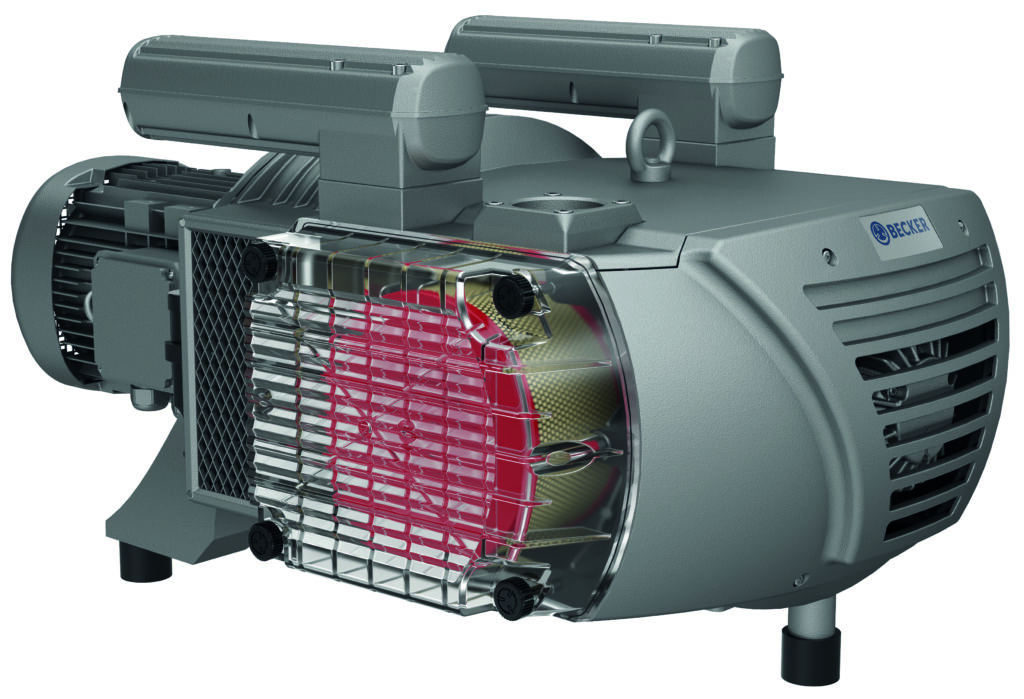

HOW ROTARY VANE VACUUM PUMPS WORK

In general, a single-stage rotary vane pump is designed with a circular rotor rotating inside a larger circular compression chamber cavity. The centers of these two circles are offset, creating an eccentricity. Vanes set into the rotor slide in and out with the help of centrifugal force. As the rotor turns, the vanes maintain contact with the chamber interior wall, creating areas of variable volume, due to the rotor offset.

With each eccentric rotation, a sliding vane opens up a region of lower pressure within the compression chamber. As the inlet gas is pushed around the rotor by the vanes, the offset between rotor and cavity captures the gas and forces it to exit the pump. This creates a vacuum effect which equalizes the higher pressure gas in the system with the lower pressure inside the compression chamber. The net result is a vacuum pressure force pulling gas out of the system.

In an oil-lubricated rotary vane pump, a thin coating of oil helps maintain a seal between the vanes and the cavity wall. Other styles of rotary vane pumps operate “dry” without the need for oil. Instead, they use self-lubricating, carbon-fiber composite vanes that contact the cylinder wall directly.

HOW MUCH DO ROTARY VANE PUMPS COST IN COMPARISON TO OTHER VACUUM PUMPS?

The initial cost of a rotary vane vacuum pump can run more than 10 times higher than the cost of a single Venturi unit, excluding the air compressor. However, a comparison of the total initial overhead might show large capital investment savings for the rotary vane pump vs. the Venturi system, along with significant yearly maintenance and utilities savings.

Oil-lubricated pumps generally have the lowest initial cost of any rotary vane pump because this technology has been around the longest and the manufacturing process is well-established.The initial cost of a pump with oil-less rotary vane technology is slightly more than an oil-lubricated unit, but they require almost no maintenance, saving time and money in the long run. Touchless pump technology, sometimes called hook & claw, is the most expensive type of rotary vane pump.

Do you need a custom pump design?

Our in-house design team can help.

IDEAL APPLICATIONS FOR ROTARY VANE PUMPS

Rotary vane vacuum pumps are versatile pieces of equipment useful in food packaging and processing, manufacturing, and many other evacuation applications. They are ideal for use in reducing a system from atmospheric pressure down to about 0.001 Torr. And they provide good airflow and a good vacuum rating at a reasonable price.

ROTARY VANE PUMPS VS. OTHER VACUUM PUMPS: HOW TO CHOOSE?

Becker Pumps designs and manufactures a variety of industrial pumps. Our rotary vane and other vacuum pumps are built to withstand even the toughest industrial environments and operating conditions.

For help in selecting the best vacuum pump technology for your application, let the experts at Becker Pumps guide you. Click below to learn more about our pumps now.