To wire a Becker vacuum pump, follow common practices for wiring a 3-phase induction motor with 9 post terminals.

The most common motor design for industrial pumps uses three phases of alternating current offset from each other by 120 degrees. Each phase is connected to two copper wire windings. As electrical current from the power source flows through the windings, it drives the mechanical rotation of the motor.

HOW TO WIRE A VACUUM PUMP

Check the nameplate or tag on the motor to find out the voltage(s) and current that it can handle. Depending on the motor type, the nameplate could show the wiring diagram printed on the motor tag or the schematic could be found inside of the terminal box. This will guide you on the proper way to connect the leads.

The diagram will show the corresponding configuration for the allowed voltages. On the wiring diagram, you will see three incoming leads labeled L1, L2, and L3. These are the three phases of electricity coming in through wires in the power cable.

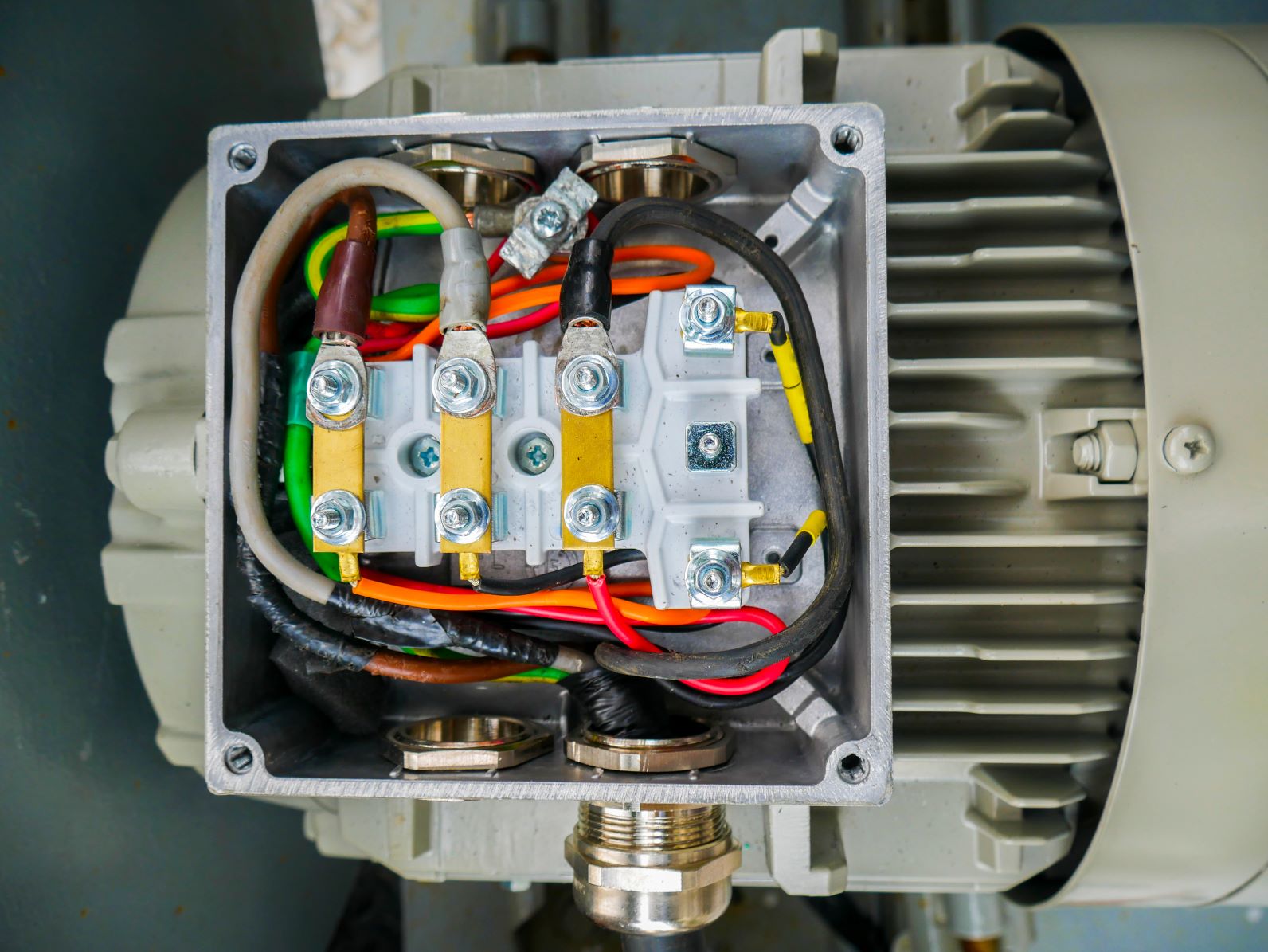

The terminals are typically labeled U1, V1, W1, U2, V2, W2, U5, V5, and W5, and can be found in the terminal box located on the motor. These symbols are given to the 9 wire pin terminals, which serve as connection points between the windings in the motor.

Becker vacuum pump motors can operate at many voltage options. For example, in North America, we use 208V-230V and 460V+-10%. The windings in the motor can be wired either for high voltage or low voltage.

Depending on the voltage of the main power, the leads can be wired together in two different configurations: low voltage (called Delta or WYE) or high voltage (called WYE).

BECKER VACUUM PUMP WIRING DIAGRAMS

NOTE: Work on the electrical wiring system should only be carried out by qualified electricians.

Practice common safety precautions, including lock-out and tag-out, before beginning any work on the electrical motor. Switch off the pump and any connected components and disconnect them from the supply voltage. Then disconnect the pump from the air supply.

For most 3-phase Becker vacuum pump models, configure the jumper bars like this depending on the applied voltage:

Match the diagram to the voltage level of your power source. Note that jumper bars can be configured for different applied voltages, so ensure you use the correct configuration.

Next, connect the leads from the mains power to your motor starter/protection or VFD to U1, V1, and W1 and connect the ground wire to the ground.

TESTING THE MOTOR

Once the wiring is complete, remove the lock-out tag-out and reconnect the power. Then quickly bump power to start and stop the motor. The motor will rotate allowing for visual checking of the motor fan rotation. Ensure the motor fan spins in the correct direction, as indicated by the rotation arrows found on the pump.

If the fan rotates in the wrong direction, you will need to reverse the polarity of the motor. Before doing this, turn off the main power to the system and lock out, tag out once again. Then switch any two of the leads, for example, switch L1 and L3. Reconnect the power and test again to ensure the pump rotates in the correct direction.

Once the pump is rotating properly, allow the motor to run while measuring the voltage and current to ensure they are within the proper range. At the same time, listen for any unusual noises that may indicate problems inside the pump.

CAUTION: Do not start the pump motor more than six times an hour, as this may cause damage to the vanes or the pump.

BECKER VACUUM PUMP WIRING SPECIFICATIONS

Becker pump models operate on specific voltage and amperage ratings. The necessary wire size varies based on the power supply voltage. For instance, the VTLF 2.250SK model requires a size 8 AWG wire when powered by 230V and a 12 AWG wire for 460V operation.

Please refer to the chart below for general specifications. It’s crucial to consult a qualified electrician to verify the appropriate wiring size and ensure safe and compliant installation in your specific facility.

CONTACT THE VACUUM PUMP EXPERTS AT BECKER FOR TECHNICAL SUPPORT

At Becker Pumps, we are known globally as experts in manufacturing and servicing high-quality vacuum pumps for a wide range of industries. We provide mobile service and customer support, including training that covers vacuum and pump basics, electrical engineering, specific product training, and everything in between.

Call Becker Pumps’ Technical Support team today for assistance with your vacuum pump wiring needs.