CENTRAL MEDICAL VACUUM PUMP TECHNOLOGY

With today’s medical vacuum pump technology, a facility can strengthen its operations with better reliability and functionality. A high-quality vacuum system with the right features gives your healthcare facility a competitive advantage.

Before purchasing a medical vacuum system, a buyer should fully understand the standard, advanced, and optional medical vacuum pump features available. This blog will not only help explain the modern technology out there so you can make the best choice for your operations but will also demonstrate the benefits of choosing Becker Pumps.

UNDERSTANDING PUMP TECHNOLOGY

Medical vacuum pump technology deeply affects a system’s functionality. Given the critical nature of a vacuum system, it’s important to understand how each piece of technology contributes to reliability and ease of operation.

Here’s a list of standard terms, functions, and medical vacuum pump features you should know.

LEAD/LAG OPERATION

Critical vacuum systems are always equipped with more than one pump. The lead pump runs until the suction demand reaches the pump’s limit, then the lag pump kicks in until the demand is met. This cascading control saves on energy plus wear and tear on equipment.

AUTOMATIC ALTERNATION

Automatic alternation equalizes the wear between pumps. The first pump to run will not activate again until all other pumps run equally. Sharing the duty cycle this way extends the service interval and equipment lifespan.

REDUNDANT TRANSFORMERS

Having redundant transformers ensures a reliable electrical supply to a vacuum system. Becker uses a relay that automatically switches from a failed unit to a backup unit, triggering a backup indicator light and alarm.

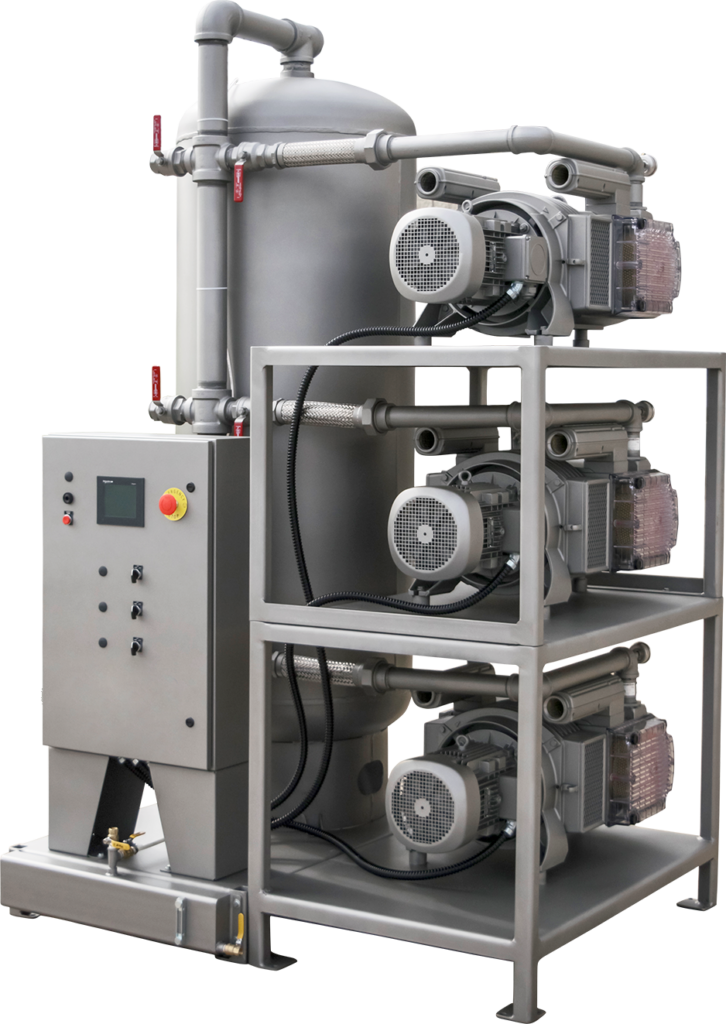

EXPANDABLE, MODULAR, AND COMPACT

In terms of a medical vacuum system, an expandable, modular, and compact setup can grow as your facility grows. Becker vacuum systems can easily expand from duplex to sextuplex (6-pump system), with modules that quickly bolt together, allowing you to mix and match to meet your operational requirements.

Our Becker systems are designed to have a small footprint, expanding vertically to save space. Most pump expansion projects take about an hour, and there’s no need for a shutdown.

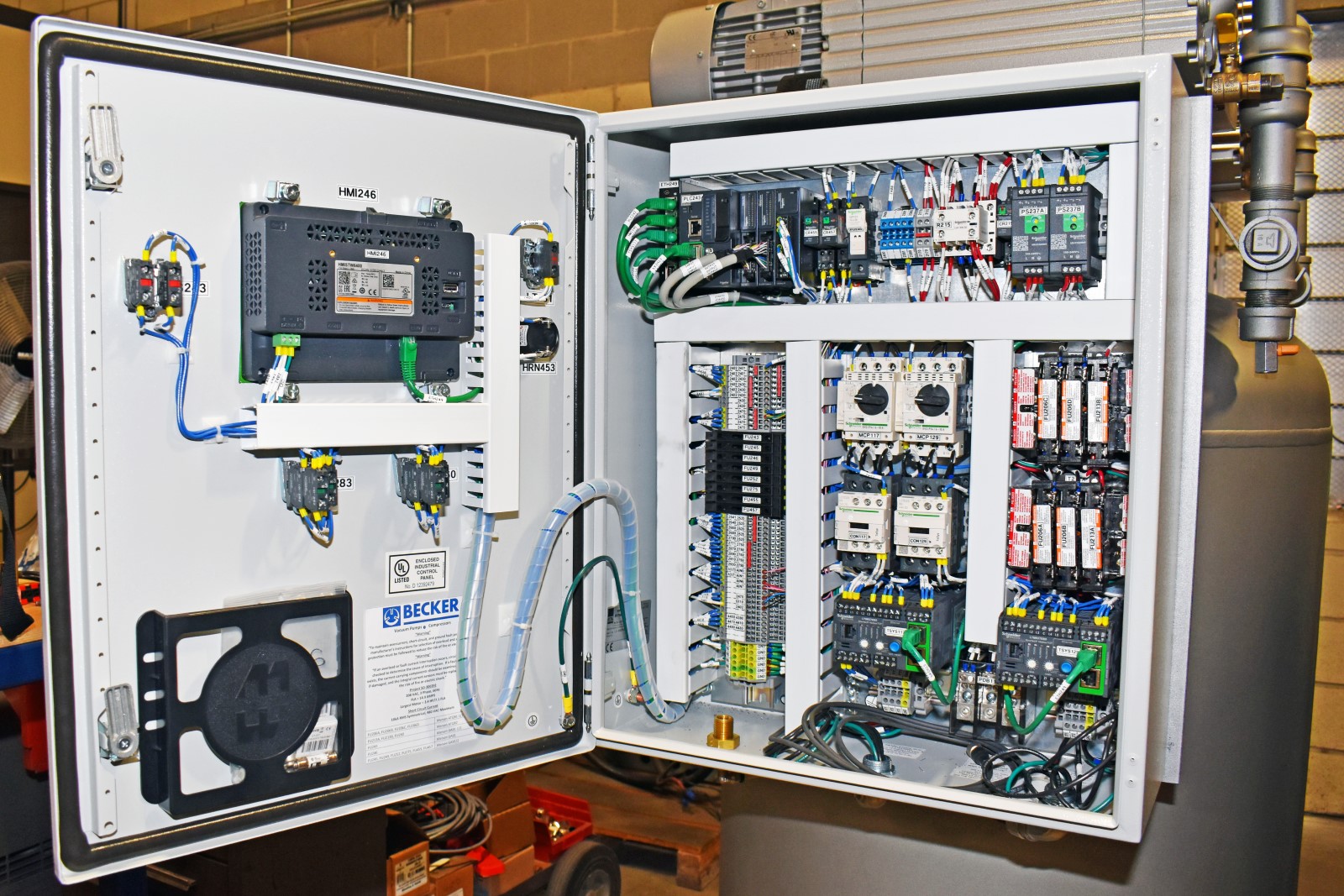

PROGRAMMABLE CONTROLLER

Multi-pump systems are best controlled by a Programmable Logic Controller (PLC). It’s a rugged, industrial solution for superior pump control. Even when expanding a vacuum system, the same Becker PLC can be used without any additional programming.

BLEED VALVES

Servicing the inlet filter on some pump systems is simpler with bleed valves that help vent the vacuum in the inlet line so you can remove the filter cover.

RESERVE PUMP ALARM

A red light and tone alarm will signal when a medical vacuum system is operating on the reserve pump. The alarm can also indicate low vacuum, low oil level, high exhaust filter pressure, high discharge temperature, and other situations that might need attention.

PRESSURE TRANSDUCER

A pressure transducer is a highly accurate device that keeps the vacuum system operating between two pressure set points.

QUIET & VIBRATION-FREE

When referring to rotary operated equipment, like oil-less and oil-lubricated pumps, quiet and vibration-free means a unit runs smoothly without pulsations. Becker’s pumps have built-in sound-dampening technology and don’t require a special foundation to control vibration.

AIR-COOLED / NO WATER

All Becker pumps are air-cooled meaning they don’t require water for cooling or operation. This feature eliminates sewer/water infrastructure needs, thereby removing the potential for water pollution.

HOOK & CLAW vs OIL-LESS vs OIL-LUBRICATED ROTARY VANE

There are a few dominant medical vacuum pump types: Hook & Claw, Oil-Lubricated, and Oil-Less. Here’s a high-level overview of these technologies.

- Hook & Claw: An energy-efficient technology that uses two rotating “claws” to compress gases, creating a vacuum. Hook & claw pumps operate without oil (other than gear lubrication). They produce more noise than other pump technologies.

- Oil-Lubricated Rotary Vane: A pump type that uses rotating oil-lubricated vanes which create a vacuum. These pumps run quietly but require more maintenance than oil-less technology.

- Oil-Less Rotary Vane: Works like the oil-lubricated pump, but it’s made to operate dry. This technology requires less maintenance but more vane replacement than its lubricated counterpart. It’s also slightly louder than the oil-lubricated pump.

THE BENEFITS OF CHOOSING BECKER

When safety is at stake, high-quality equipment pays off in terms of reliability. At Becker, we make some of the most reliable pumps in the business, and we’ll help you choose the units that support your operations best.

Becker medical vacuum systems use heavy-duty, high-efficiency motors, are guaranteed to meet current NFPA 99 standards, and come with a 3-year warranty. And, as a manufacturer, we can deliver a level of hands-on training and service that goes beyond anything offered by a third-party seller.

Our system sizing method is based on experience gained from over a thousand installations and includes up-to-date terminal requirements relevant to most of today’s healthcare facilities. To learn more about sizing a medical vacuum system, click below.