How much does new or replacement pump components for your hospital’s medical vacuum system cost? We take a look at what goes into determining your investment in this critical piece of healthcare infrastructure and how smart choices today can help save money in the long term.

WHAT GOES INTO VACUUM PUMP PRICING?

A hospital’s medical gas system is a critical, life-sustaining part of the essential services provided by healthcare facilities. Ensuring reliable, effective vacuum equipment is always available is essential to patient safety. How do we ensure that money spent to install or upgrade parts of the system’s equipment will help meet this goal while also delivering efficiency and value?

TALK TO THE EXPERTS

Whether you are a facility or project manager, an equipment supplier, or an OEM, you must speak to vacuum experts to walk you through the design and pricing considerations typically used when supplying vacuum equipment.

Talking to an experienced industry player can provide valuable insights into things like:

- Relevant regulatory and safety codes,

- Location and noise considerations,

- System redundancies and fail-safes, and

- Balancing upfront expenditure with long-term efficiencies.

FACTORS AFFECTING PRICING FOR VACUUM COMPONENTS OF MEDICAL GAS SYSTEMS

Now let’s take a look at some of the major cost points and trade-offs that affect pricing for components used in medical vacuum systems.

1. SYSTEM SIZE

The size of your facility and the types of demands it will put on your medical vacuum system is the single biggest factor in determining cost. Suppliers will look at:

- The total number of (Type A) high and (Type B) low usage terminals required

- The number of rooms requiring special services, such as operating theaters, and

- The overall mix of services being offered. For instance, an ophthalmic consulting site will not have the same needs as, say, an acute respiratory care center.

The specific vacuum services that healthcare systems are required to have are governed by the National Fire Protection Association’s NFPA 99 code. Suppliers will be able to estimate the pump capacity you will need to meet the minimum requirements laid out in the code.

Becker Pumps has its own formula based on the NFPA code for determining the total vacuum capacity you will need — as well as the most efficient way to deliver it.

For example, if you determine you need two 10-horsepower (10-HP) pumps to meet the NFPA requirement that you have redundant capacity capable of handling your entire vacuum demand, Becker might recommend you install three 5-HP pumps instead. For a comparable investment you’ll get the required redundant capacity, plus:

- More efficient energy usage

- Cheaper parts

- Easier maintenance, and

- Quieter operation.

This shows why it pays to consult with an experienced equipment provider to help balance your upfront expenditure with downstream considerations, including:

- Long-term power consumption

- Additional capacity to meet future needs

- Expandability, and

- Total maintenance costs over time.

2. TECHNOLOGY USED IN THE MEDICAL VACUUM SYSTEM

Once you know how much capacity you need to install, you can work with suppliers to determine what kind of pump technology is the best fit for your needs. Some major considerations include:

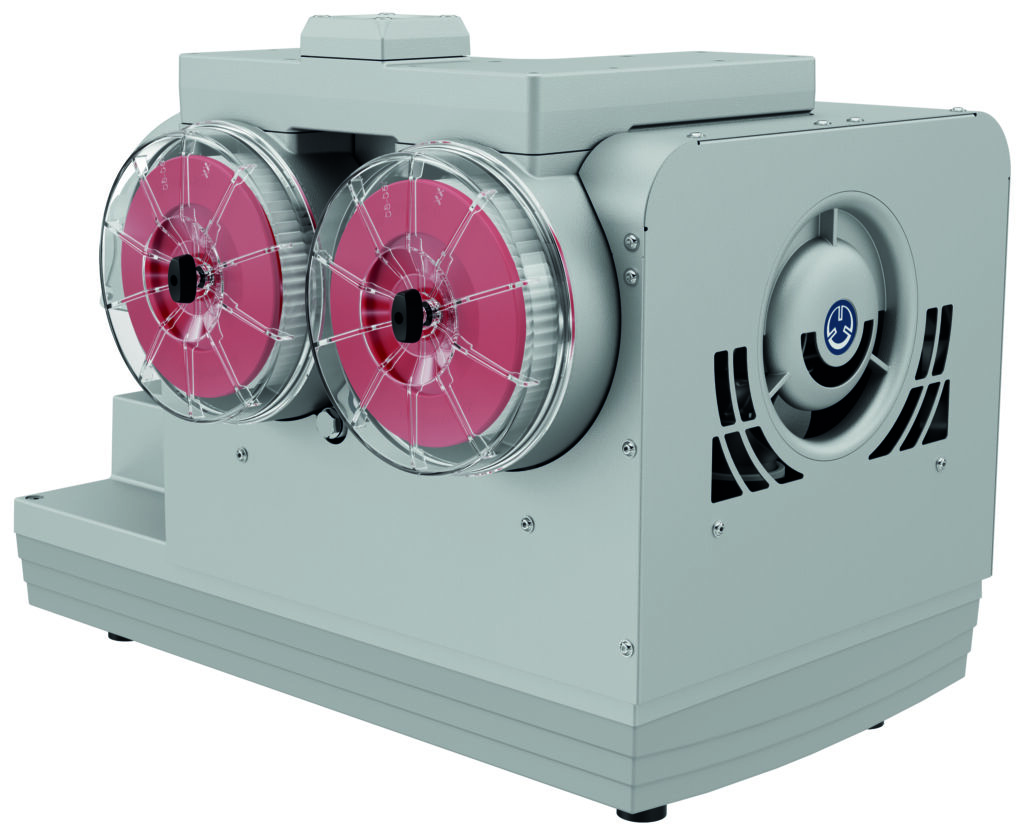

- Air-cooled or water-cooled pumps: Air-cooled vacuum pumps are usually pricier than water-cooled units but are also smaller and quieter and do not require high-maintenance water or sewer connections. All Becker pumps are air-cooled.

- Pump type: Common technologies like hook and claw vacuum pumps and oil-lubricated and oil-free rotary vane pumps offer different combinations of features including energy, efficiency, ease of maintenance, and low noise operation. Becker can help you identify the best technology combination for your facility.

3. SAFETY AND EFFICIENCY EQUIPMENT

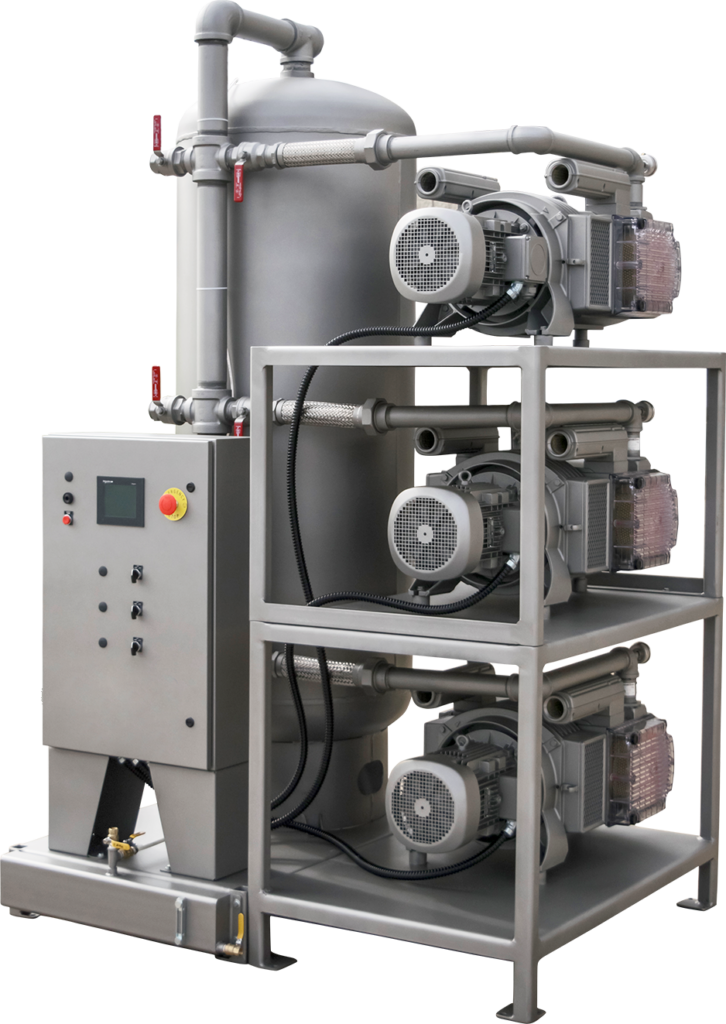

Hospital medical vacuum systems also include specialized pump equipment designed to ensure safety, improve pump efficiency and reduce wear and tear during years of continuous operation under fluctuating demand loads. Examples of this equipment include:

- Redundant transformers providing backup power

- Lead/lag systems that shift excess demand to backup pumps

- Automatic alternation systems that ensure pumps share the workload equally, and

- Programmable controllers that allow single-point management of multi-pump systems.

While these systems add to the up-front cost of your system, they save money for your facility over time by reducing energy consumption and maintenance costs.

4. PICKING A BRAND

Choosing the brand of vacuum pump to support your vacuum system is a major decision. Ideally, you want to build a relationship with a partner who will work with you to solve mechanical and integration problems, and who will stand behind their equipment for years to come. If this is the case, then investing in a long-term partnership with a manufacturer is a smart decision.

While generic suppliers may be cheaper than a name-brand supplier like Becker Pumps, they are often unable to support their cut-rate imported equipment with spare parts or established service infrastructure. At Becker, we make our own equipment and support it with our own sales, service, and replacement parts network.

BECKER PUTS IT ALL TOGETHER

A wide range of factors goes into determining how much new or replacement equipment for your central medical vacuum system will cost.

At Becker, we work with you to identify the best mix of equipment for your needs and then deliver high-quality units that will deliver safe, efficient, and reliable service for years to come.

Becker helps customers cut out the middle man by engaging directly with an equipment manufacturer who understands their needs.

We also offer our customers:

- Extensive experience in matching pump capacity to system size using our own formula and experience from more than a thousand installations

- Vacuum pump equipment guaranteed to meet NFPA 99 standards

- A three-year warranty on all pump equipment

- Unrivaled hands-on training, and

- Advice and on-site inspections from factory-trained technicians.

Click below to learn more about how Becker’s vacuum pump solutions can work for you.