Have you ever tried to finish a report with construction noise outside? Almost everyone can attest to the stress caused by repeated loud noise in the workplace. Besides unwanted headaches, permanent hearing loss is a real concern.

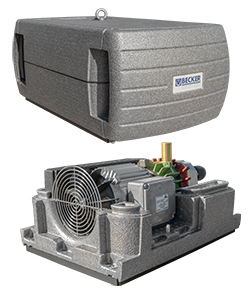

“Becker Pumps’ acoustic enclosures provide soundproofing for pump operations in sensitive work environments.”

The Benefits of Sound Enclosures

Noise is relative. While the sound level in one location may be fine, it may be completely disruptive in another.

Becker Pumps’ acoustic enclosures provide soundproofing for pump operations in sensitive work environments, reducing stress, and the chance of permanent hearing damage. High noise absorption materials reduce vacuum pump noise by up to six times, without adversely affecting your vacuum pump efficiency.

- Sound absorbent, 6x quieter (10-18 dBA noise reduction)

- Impact-resistant

- Chemical resistant

- Lightweight

- Custom-fit for Becker Pumps

- Field installation on most models

These enclosures are fully compatible with all Becker vacuum pumps and can be used throughout your facility to keep operational noise to a minimum. Besides reduced vacuum pump noise, Becker Pumps’ enclosures also eliminate ambient dust and dirt from building up on the pump while the integrated fans keep the pump cool.

A Sound Enclosure or Something Else?

You may not even need a traditional sound enclosure. It may be that you only need to:

- Plumb the outside exhaust,

- Discharge the silencer, or

- Remotely locate the pump.

Many options can save your system. Be sure to reach out to one of our experts to find the right fit for your pump.

One Size Does Not Fit All

Becker’s sound enclosures are custom designed for each pump. Our smaller pumps are made of rigid foam. Larger pumps are made from metal with rigid foam insulation, and the fans have a separate electrical connection; either 110v or 220v.

While some enclosures on the market claim to fit any pump, Becker’s are designed specifically for each individual model to fit its specific needs. The turnaround time for a custom enclosure is about four to six weeks.

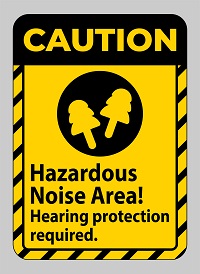

How Loud is Too Loud?

The effects of noise-induced hearing loss can be profound, limiting your ability to hear high-frequency sounds, understand speech, and seriously impairing your ability to communicate.

According to the Occupational Safety and Health Administration (OSHA), exposure to high levels of noise can cause:

- Permanent hearing loss

- Physical and psychological stress

- Reduce productivity

- Interfere with communication and concentration

- Contribute to workplace accidents and injuries by making it difficult to hear warning signals

Over the course of a lifetime, extended or repeated exposure to loud noise and sounds at or above 85 decibels (approximately the level of a vacuum cleaner) can cause permanent damage to a person’s hearing. The damage can be in the high-frequency range of hearing, the low frequencies, and/or anywhere in between. Researchers have found that people who are exposed over long periods to high decibels are at a much greater risk for hearing loss.

OSHA Requirements

All workplaces must comply with OSHA requirements. OSHA requires employers to implement a hearing conservation program when noise exposure is at or above 85 decibels averaged over 8 working hours, or an 8-hour time-weighted average (TWA).

Hearing conservation programs strive to:

- Prevent initial occupational hearing loss,

- Preserve and protect remaining hearing, and

- Equip workers with the knowledge and hearing protection devices necessary to safeguard themselves.

Becker vacuum pump, compressor, and blower sound enclosures can help reduce 6x the noise by creating a barrier between the pump and the outside environment. Each Becker sound enclosure is light, compact, and fits the pump tightly. It provides essential cooling in specific spots so that the unit continues to operate effectively.

Mitigating the Damage

Exposure to loud noise kills the nerve endings in our inner ear. More exposure results in more dead nerve endings, resulting in permanent hearing loss that cannot be corrected through surgery or with medicine. Noise-induced hearing loss limits your ability to hear high-frequency sounds and understand speech, which seriously impairs your ability to communicate. Hearing aids may help, but they do not restore your hearing to normal.

Do you need a custom pump design?

Our in-house design team can help.

Getting the Right Sound Enclosure

Becker pumps are built to be the quietest vacuum pumps and compressors available. Sound enclosures can be found elsewhere, but no one understands the specific cooling requirements better than we do. Each Becker sound enclosure is light, compact, and fits our pump like a glove, providing essential cooling in just the right places.

Becker Pumps Corporation is a leading manufacturer of vacuum pumps, compressors, and regenerative blowers. We also provide sales, service, and replacement parts across the United States, Canada, and Mexico.

WE BELIEVE IN

PARTNERSHIP

Let us help you get the right sound enclosure for your environment. Click below to learn more.