Becker has designed a comprehensive handbook for the use of our distributors and customers as an aid in the designing of applications involving vacuum and low pressure compressed air.

Just some of what you’ll find in the complete handbook includes:

Similarity of Units

Electricity, pressure, and vacuum have analogous units: force, current, resistance, conductance. Electricity is made up of volts, amps, ohms, and mho. Pressure and vacuum consist of torr, CFM, and pressure rise and drop.

CFM vs. SCFM vs. ACFM

There are different cubic feet per minute you’ll find when working with various pumps. Displacement, mass flow, and volumetric flow are all important pump measurements.

Motor Cycling Guidelines

Electric motors have specific NEMA guidelines for the number of starts per hour and the period between stops and starts they can tolerate. Guidelines also include motor minimum intervals and minimum required horsepower.

Noise

Noise measurements and prolonged permissible exposure times are important aspects of working with a commercial vacuum.

For example, the sound pressure level, or noise, is measured on an exponential scale. An increase of 3 dB is a doubling of the noise. A 10 dB increase is 10 times noisier; 20 dB is 100 times noisier. It takes a 3 dB sound level increase for it to be perceptible to the human ear.

Exposure to different noise levels at different times requires that the sum of the exposure time percentages (actual time at each sound level divided by the permissible time at each sound level) cannot exceed unity.

“At Becker Pumps, we offer a trial & test program to all serious customers. Free vacuum pump testing allows you to evaluate a machine thoroughly.”

Altitude Correction for Regenerative Blowers

A given percentage decrease in density due to altitude equals the same percentage decrease

of pressure, but the same ACFM.

For example, a blower that produces 110 ACFM at 40 in. H2O at sea level = 110 ACFM at 35.72 in. H2O at an altitude of 3000 feet(26.62 in. Hg Bar. Pr.): [40 x 0.107 = 4.28; 40 – 4.28 = 35.72]

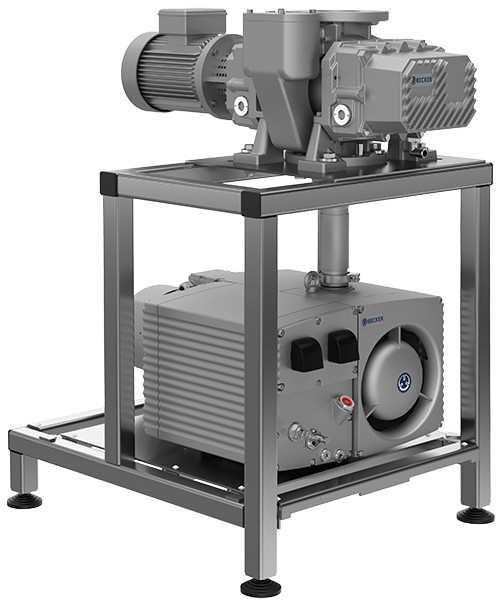

Vacuum System Sizing Multiplex Systems

The majority of central vacuum systems are designed with redundancy included. The following method is the most common. The Peak Calculated Load (PCL) is the maximum anticipated load the system is expected to meet.

Duplex, Triplex, and Quadruplex pumps are all part of a multiplex system.

Conductance

Conductance (C) is the reciprocal of resistance, or pressure drop (∆P), expressed in terms of volumetric flow.

When designing a system, the calculated conductance should be at least ten times the ACFM (i.e., if the volumetric flow at the operating pressure is 150 ACFM, the conductance of the system should be at least 1500 ACFM).

Receivers

It is important to size a receiver to equalize pressure and calculate the final equalized pressure.

For Example:

Where

P1 = Initial pressure (Torr)

P2 = Final, equalized pressure (Torr)

P3 = Initial volume (ft3)

subscript a = high pressure (low vacuum) chamber

subscript b = low pressure (high vacuum) chamber

Rule of Thumb

To reduce the absolute operating pressure by half requires twice the pump capacity. Pumping the same load in half the time requires twice the pump capacity.

Increasing Pump Capacity

To increase flow while maintaining the same ultimate pressure, place pumps in parallel.

To decrease the ultimate pressure while maintaining the same flow, place pumps in series (flow will be determined by the first pump in the series).

To increase both flow and ultimate pressure, place a rotary lobe (Roots-type) positive displacement blower as the first pump in a series with a Dekatorr type pump.

Using a Pump as a Flow Meter

Based on the principle that all positive displacement pumps have linear mass flow curves.

- Set any pump control switches to “manual” or, if none are used, place jumpers across the vacuum switch contacts. The pumps must not cycle on and off during this test. Only run one pump.

- Close the isolation valve at the inlet of the pump and measure the best (ultimate) vacuum it can produce. Use a good quality pressure gauge.

- Open the isolation valve and let the pump run until the vacuum reaches a stable level (does not rise or fall).

- Refer to the performance curve for the pump and read the flow produced at the vacuum level at which the system stabilized.

This is the total flow for the entire system at that moment. Monitor it using the same method at different times during the day and during different days to establish variations in the requirements.

Note that some manufacturers rate their pumps in ACFM, while others rate theirs in SCFM.

WE BELIEVE IN

PARTNERSHIP

Download Our Rules of Thumb Handbook

This is just a portion of what you’ll find in our handy technical guide. Learn much more about vacuum and low pressure compressed air by downloading Becker Pumps’ Rules of Thumb handbook.