Healthcare and laboratory professionals rely on medical systems to provide patients with much-needed critical care. By properly servicing your medical vacuum system, you help them succeed in their roles. After all, superior care requires superior equipment.

This blog will explore the maintenance needs of several vacuum systems, explain the benefits of mobile service, and discuss Becker’s outstanding maintenance support.

REGULAR MAINTENANCE OF MEDICAL VACUUM SYSTEMS

It’s no surprise that different vacuum systems require different types of upkeep. Service for your specific medical vacuum system will have a schedule and set of tasks that are unique to your equipment.

Note: Always consult a pump’s operating manual for manufacturer-recommended maintenance tasks and frequency.

HOOK & CLAW PUMPS

With contactless technology, hook & claw pumps require minimal oil to function, and there’s no wear and tear on parts. Compared to other medical vacuum pump types, these units have very few maintenance needs.

Typical service tasks include:

- Checking/replacing the inlet filter(s) as necessary

- Checking gear oil and replacing as necessary

- Checking for excessive noise

- Checking for excessive vibration

OIL-LUBRICATED ROTARY VANE PUMPS

This type of pump uses oil during operation and requires more maintenance than hook & claw or oil-less rotary vane technology. Vanes are prone to wear and must be checked and replaced after extended operation.

Typical service tasks include:

- Checking the oil level

- Checking the oil filter

- Checking the oil condition and replacing it as necessary

- Checking wear on vanes and replacing them as necessary

- Checking bearing lubrication

- Checking/replacing the inlet filter(s) as necessary

- Checking for excessive noise

- Checking for excessive vibration

OIL-LESS ROTARY VANE PUMPS

With no need for oil, this pump does not have oil-related maintenance needs. However, vanes are still prone to wear and may degrade more quickly than an oil-lubricated unit.

Typical service tasks include:

- Checking wear on vanes and replacing vane(s) as necessary

- Checking bearing lubrication

- Checking/replacing the inlet filter(s) as necessary

- Checking for excessive noise

- Checking for excessive vibration

LIQUID-RING PUMPS

Extensive maintenance is required for a liquid-ring pump. The liquid used as a seal (typically water) undergoes a pressure change during operation, potentially leading to cavitation of vapor bubbles that may severely damage a pump unit.

Typical service tasks include:

- Checking the temperature of the liquid used for sealing

- Checking bearing temperature

- Checking for wear and/or leaks on the shaft seal

- Checking for wear and/or leaks on the mechanical seal

- Checking for scale buildup on vanes

- Checking sealing liquid lines

- Checking for excessive noise

- Checking for excessive vibration

ON YOUR WAY TO BETTER PUMP MAINTENANCE

Maintenance scheduling for medical vacuum pumps is based on hours of operation—every healthcare facility uses its vacuum system differently and therefore requires a customized maintenance plan.

For a new pump, Becker advises carrying out maintenance at three months and then evaluating the condition of the unit and components. Your maintenance team can use this information to develop a baseline for future upkeep.

Dealing directly with a pump manufacturer is always the best way to answer questions about maintenance. A manufacturer’s expertise can guide a maintenance strategy that provides the best service for your medical vacuum system.

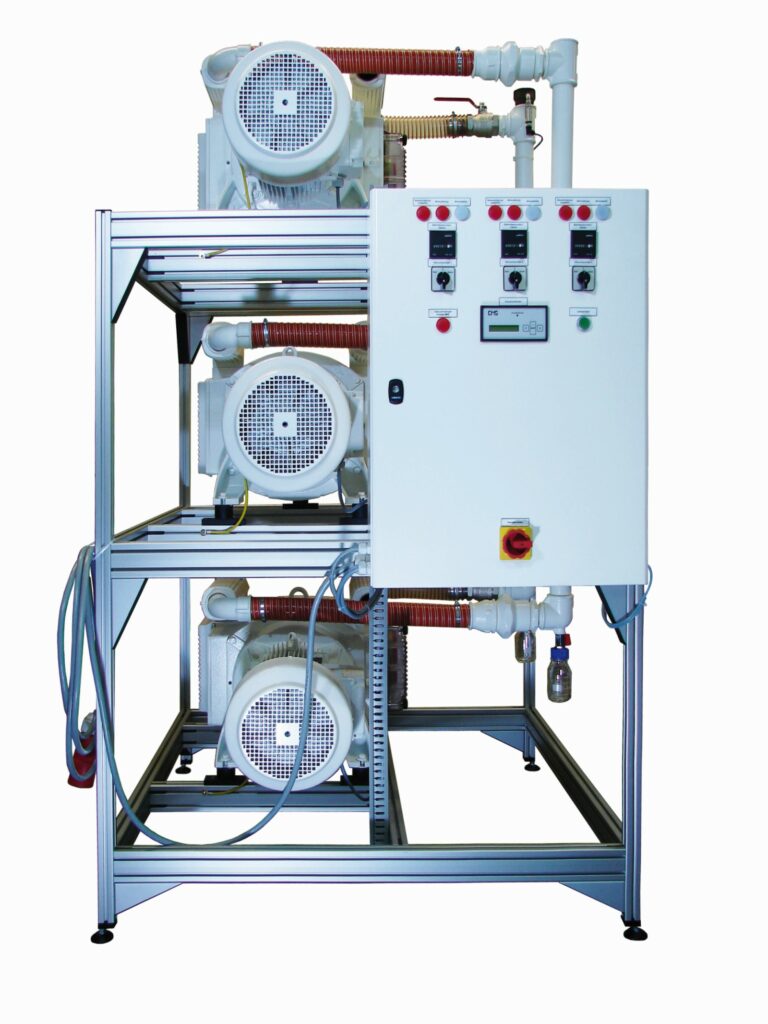

MOBILE SERVICING BY BECKER PUMPS

At Becker, we know how critical a medical vacuum system is to a healthcare facility, which is exactly why we offer mobile servicing for our vacuum pumps. Our factory-trained technicians will come to your site, thoroughly inspect pumps, and carry out the necessary maintenance.

As part of Becker Mobile Service, we offer:

- Customized service scheduling that fits within your budget

- Only Becker Genuine parts for repairs or replacements

- Technical assistance and answering questions while we’re on-site

- Transparent pricing—no hidden charges or additional work without authorization

Our mobile service frees up an operations team and gives you peace of mind that your medical vacuum pumps are getting the care they deserve.

BECKER’S MANUFACTURER TRAINING

Confidently take control of pump maintenance with training opportunities for technicians and staff. From operation to application to maintenance, the more your staff understand the system, the better they’ll maintain it.

Our product training includes:

- Pump installation

- Control panel specifics

- Pump startup and operation

- Troubleshooting

- Ongoing maintenance

Becker’s manufacturer training supports oil-free rotary vane, oil-lubricated rotary vane, or hook & claw pumps.

PREMIUM SERVICE FOR YOUR MEDICAL VACUUM SYSTEM

There’s no better expert than a Becker factory-trained technician to answer questions about your Becker pump. Our service focuses on meeting your schedule, budget, and operational needs to ensure reliable support.

We offer a range of solutions to service your medical vacuum pump, from expert advice to mobile assistance to product-specific training. With the right strategy in place, a Becker pump will support your medical vacuum system for years to come.