This case study focuses on Ripple Road Maple, a renowned maple syrup producer based out of Norwich, NY. An innovative company, Ripple Road Maple stays up to date with the best and newest technologies in their industry to ensure their products are of the highest quality. Our friends at Ripple Road Maple found themselves in pursuit of improving their operations so they trusted Becker Pumps to provide the solution.

THE PROBLEM: A NEED FOR IMPROVED EFFICIENCY

The Walling family built Ripple Road Maple’s sugarhouse in 2012 and had been using an Indiana Liquid Ring Vacuum Pump for their operations since their business’s inception. Though this pump helped them produce a lot of high-quality maple syrup over the years, it began presenting them with challenges. The pump consumed a significant amount of electrical power, leading to high operational costs. The pump generated quite a bit of noise which began to disrupt their work environment. Lastly, the pump was not designed to maintain the desired 29” HgV when weather conditions are prime for a deep vacuum operation.

THE SOLUTION: U 5.101 OIL-LUBRICATED VANE PUMP

With the challenges noted above, Ripple Road Maple came to Becker Pumps with the desire to improve their vacuum technology. Once our staff had diagnosed the problems caused by the original pump, and learned about Ripple Road Maple’s unique operational requirements, the solution became clear: Ripple Road Maple needed the U 5.101 Oil-Lubricated Rotary Vane Vacuum Pump. The U 5.101 is a highly efficient deep vacuum, lubricated rotary vane pump, making it ideal for maple syrup production.

THE RESULTS: 5 SIGNIFICANT IMPROVEMENTS

The U 5.101 Oil-Lubricated Rotary Vane Vacuum Pump yielded excellent results for Ripple Road Maple. Listed below are the five primary operational improvements achieved:

- Improved Customer Satisfaction: The consistent and superior end vacuum level provided by the Becker pump resulted in enhanced product quality. Ripple Road Maple was also able to deliver more maple syrup to its customers, thereby improving their customer satisfaction and loyalty.

- Reduced Electrical Costs: The energy-efficient design of the Becker pump led to a notable reduction in electrical consumption. Ripple Road Maple experienced substantial savings on their energy bills, positively impacting their bottom line.

- Reduced Sound Levels: The Becker pump’s lower noise emissions created a quieter work environment, contributing to improved employee comfort, concentration, and productivity.

- Enhanced Efficiency: The Becker pump’s reliable and efficient operation resulted in streamlined production processes. The pump’s robust performance minimized downtime, ensuring uninterrupted maple syrup production, and improved operational efficiency.

- Increased Vapor Handling: Moisture entering a vacuum pump can cause major issues. However, Becker’s increased vapor tolerance (specifically enhanced for the Maple market) allows for a full 29” HgV while removing any vapor carryover from the releasers.

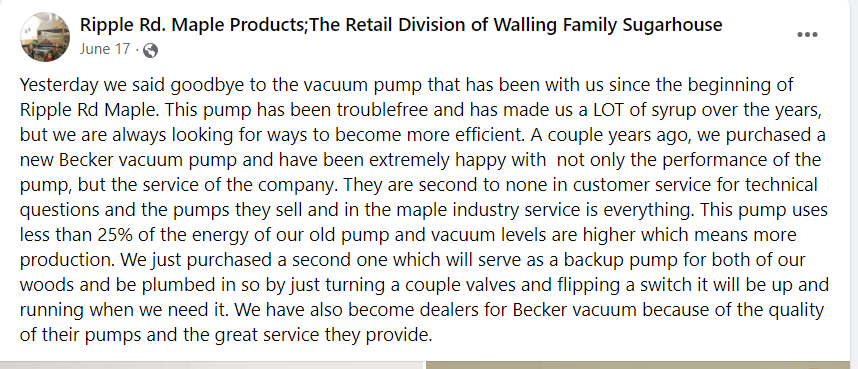

Excited about its improved operational efficiencies and a strong growing relationship with Becker Pumps, Ripple Road Maple posted what’s below to their social media account.

BECKER PUMPS AND RIPPLE ROAD MAPLE: AN ONGOING PARTNERSHIP

Becker Pumps has been proud to work with Ripple Road Maple and was thrilled to hear about its operational improvements. Ripple Road Maple was so enthusiastic about their Becker pump that they have become a Preferred Reseller of Becker’s products, reinforcing their commitment to excellence in Maple Syrup production. This partnership has been greatly appreciated by both parties and it’s one that will continue to thrive!