Farms specializing in maple sugar extraction implement vacuum pumps into their operations to increase yields and improve overall efficiency.

Operations of all sizes, including small and developing farms, can enjoy the benefits of a small vacuum pump for maple sap extraction. Investing in the right vacuum pumps is particularly important for these smaller farms, however, and figuring out which pumps meet your needs while still being affordable to buy and operate can be a challenge.

Below, we provide an overview of how vacuum pump technology works for maple sap extraction, the benefits of adding vacuum pumps, and key considerations to make when shopping for vacuum pumps.

VACUUM PUMPS FOR MAPLE SUGAR EXTRACTION: THE BASICS

Understanding how a small vacuum pump for maple sap extraction works can be very helpful in figuring out which pump is right for your farm.

Sap flows from a tree when the pressure inside the stem is greater than the pressure in the atmosphere outside. When the pressure inside the tree decreases or there is little difference in pressure inside and outside the tree, the sap flow slows down.

Vacuum pump systems typically include the small vacuum pump for maple sap, tubing, collection chamber, and storage tank. These systems work well because they allow users to control the pressure around an extraction point.

The pumps decrease the pressure in the tubing leading to the extraction point. This process speeds up the sap flow rate since the pressure inside the tubing remains lower than the pressure inside the stem.

VACUUM PUMPS FOR MAPLE SUGAR EXTRACTION: THE BENEFITS

As mentioned above, sap extraction is heavily influenced by atmospheric conditions. Farms may find that extraction on days when there is a low-pressure differential inside and outside the trees is a challenging, if not impossible, task. Running into a number of those days during a sap season can lead to major decreases in yield and overall bad seasons.

Vacuum pump systems help avoid rough seasons by enabling users to extract even on days when atmospheric pressure is not ideal. Since farms that use vacuum pumps are less dependent on atmospheric conditions for their production, they can continue operating through those bad patches.

Because vacuum pumps allow sap to flow more quickly, they are also beneficial for increasing production during short thaw periods when there is a limited amount of time to extract sap.

Overall, vacuum pumps lead to higher yields for maple sap extractors. In fact, vacuum pumps can increase sap production by 50% to over 200%.

CHOOSING THE RIGHT SMALL VACUUM PUMP FOR MAPLE SAP EXTRACTION

COST

The initial expense of purchasing a vacuum pump system is an important consideration, particularly for small farms. Remember that the cheapest pumps on the market may end up costing you more money over time if they require frequent repairs and are difficult to service.

The best investment for any size operation will be a reputable, well-built vacuum pump system designed to meet the particular needs of map sap extraction. These systems are less likely to have issues that cut into your budget when operating in harsh, outdoor conditions. They should also be able to be maintained affordably and not require expensive parts to be serviced.

SIZE

Size is another important consideration when purchasing a small vacuum pump for maple sap extraction.

Small, durable pumps able to provide deep vacuum while being incorporated into lightweight, mobile systems are a good investment for many farms. For smaller farms, pumps that offer deeper vacuum for fewer taps can increase yields without being expensive to run.

Since these smaller pumps with high vacuum capabilities are less expensive to operate than their larger counterparts, they will also decrease the amount of time before you see a return on your investment.

SERVICEABILITY

At some point, your vacuum system will need to be serviced. This process can be simple and inexpensive, or difficult and costly, depending on the system you choose.

The best vacuum pumps will be easy to service and utilize inexpensive components. Those features will help reduce downtime and make regular maintenance more manageable.

DURABILITY

Maple sap extraction can be a tough job and not all vacuum pumps are cut out for it.

Select a vacuum pump that clearly states it is designed for working in maple sap extraction. These pumps are better suited for operating outdoors and in harsh weather. Just because a vacuum pump is small does not mean that it has to be fragile.

CUSTOMER SERVICE

Purchasing a vacuum system for a small maple extraction farm can be overwhelming and you might need support along the way. Be sure to purchase from a company that will be there to answer your questions, from initial inquiries and purchase through installation and maintenance.

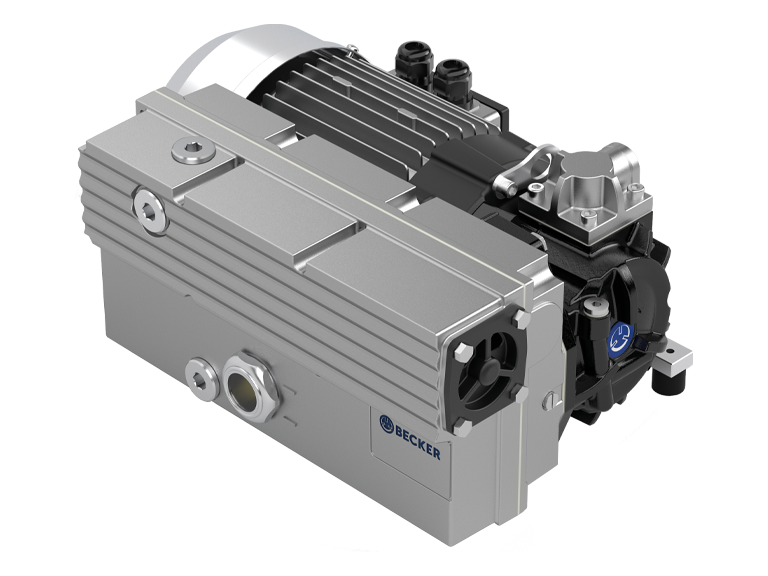

BECKER O SERIES VACUUM PUMPS FOR MAPLE SAP EXTRACTION

Models O 5.10, O 5.16, and O 5.25LXK from Becker’s O Series are well-suited for small maple farms. These pumps offer high vacuum capabilities for a lower number of taps and can be operated inexpensively compared to larger pumps designed for bigger operations.

Each model is a deep vacuum, wet displacement pump featuring an oil-lubricated rotary vane with freely-configurable service openings and high water vapor tolerance.

| Model | National CFM | Inlet Size NPT | Vacuum | Number of Taps | Data Sheet | Operating Manual | Spare Parts List |

|---|---|---|---|---|---|---|---|

| O 5.10 | 7.4 | 3/4 | 29 | 370 – 740 | view | view | view |

| O 5.16 | 11.2 | 1/2 | 29 | 560 – 1120 | view | view | view |

| O 5.25XLK | 17.6 | 1 | 29 | 880 – 1760 | view | view | view |

CUSTOMIZATION

Becker proudly offers vacuum pump customizations for farms that have unique needs. You will work with our team of experts to determine the exact specifications needed to make implementation a success and increase sap yields.

If your application requires a custom vacuum pump, click below to learn more or get in touch with us today.