Becker Pumps offers the right technology for your specific application …

IS AN OIL-LUBRICATED VACUUM PUMP THE BEST DECISION?

Becker Pumps Features:

- Rated for 100% use factor

- Can be operated outdoors

- Available in single or three phase

What Needs to be Considered

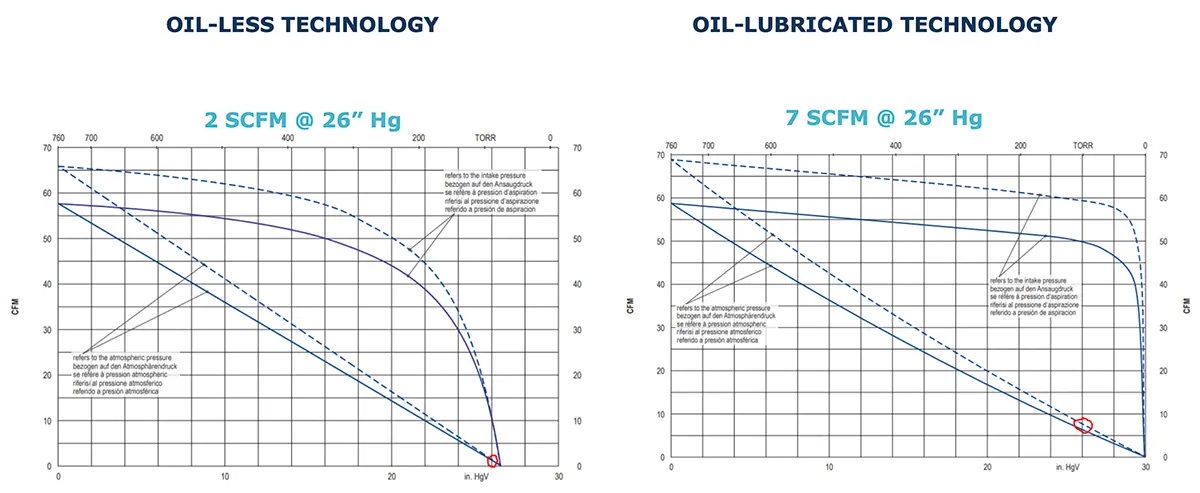

#1 – Vacuum Level

“The higher the vacuum level is, the greater the yield of sap.”

– From North American Maple Syrup Producers Manual Second Edition

#2 – Flow

OUR Recommendation: Oil-Lubricated Rotary Vane

Why? Vacuum Level, Pump Protection, and Better Flow Rates

Vacuum Level

Research has shown that adding vacuum to a maple tubing system can increase sap production 50% to over 200% over a maple season. The higher the vacuum pressure at the tree the greater the yield response.

– From New York State Tubing & Vacuum System Notebook 6th Edition

Oil-Lubricated Rotary Vane Pumps Achieve 29.90″ Hg

- Includes oversized gas ballast to eliminate water vapor

- From 620 to 43,000 Taps

Pump Protection

Oil protects pump from contaminants coming back from the process. Oil-less technologies can be susceptible to failures with any liquid ingestion.

Better Flow Rates

If your system was running at 26” Hg with an oil-lubricated pump and you replaced it with the same size oil-less pump, the vacuum level would drop to 23” Hg.

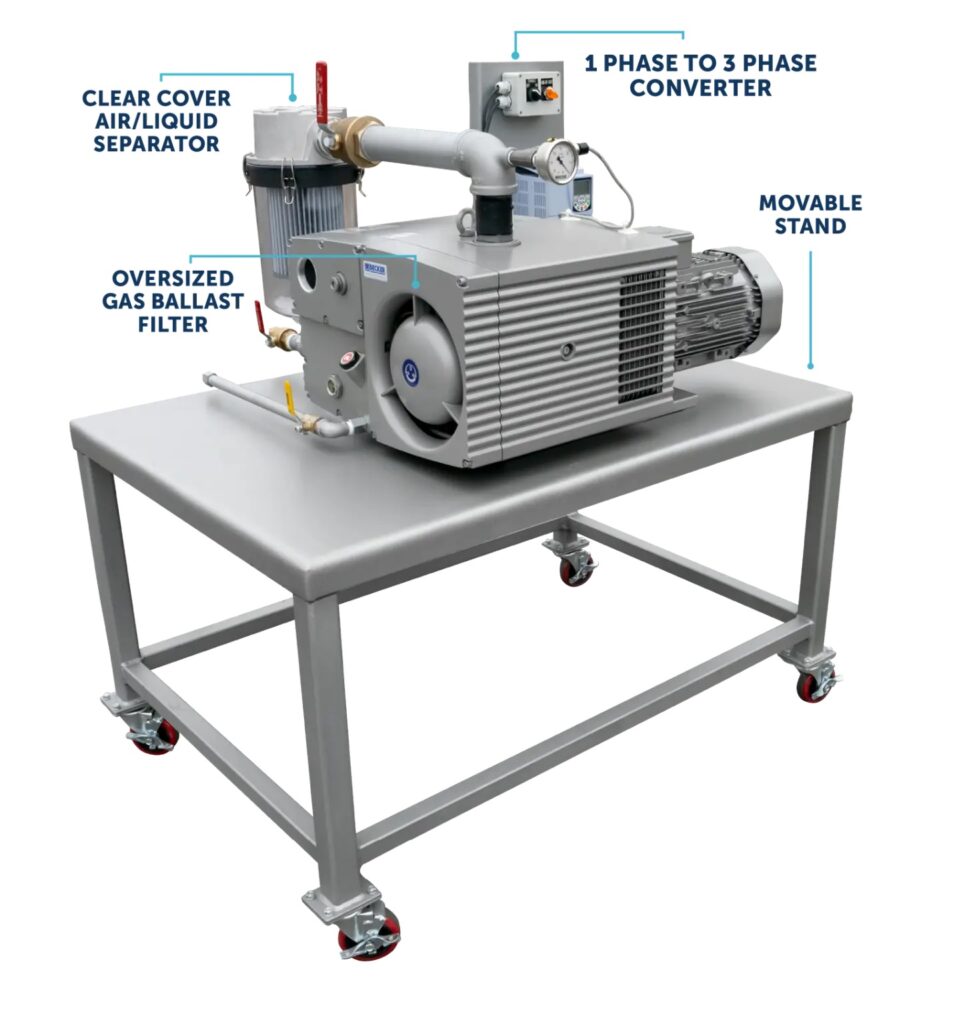

Is Water and Water Vapor Destroying Your Vacuum Pump?

Becker also offers complete Vacuum Systems to eliminate water and vapor problems

CHECK OUT ADDITIONAL ACCESSORIES TOO:

- Clear Filter – Easily see if liquid is present.

- Check Valve Assembly – Prevents reverse rotation.

- Maintenance Indicator – Know when to change oil separators.

- Vacuum Gauge – Monitors vacuum level.

And more

Contact the factory or Customer Support now for help with selecting the best vacuum pumps to fulfill your requirements.