Becker Oil-Less Rotary Vane Central Vacuum Systems

Advantage-D & Advantage-X Systems

Becker’s Oil-Less Rotary Vane Central Vacuum Systems utilize Becker’s dry rotary vane vacuum technology. The Advantage-D and Advantage-X systems are suited for medical/surgical or general industrial applications that require operating vacuum levels from atmosphere to as high as 27 in. Hg. They are available in various configurations with up to six vacuum pumps, and are nearly maintenance-free.

Our dry rotary vane vacuum systems are ideal for use where any of the following conditions are a problem:

- Where any oil mist, or aerosols, present in the discharge air could contaminate the workplace, or damage roofing membranes.

- Where oil filling, changing, and disposal is an inconvenience or a hazard.

- If oil leaks persist.

- Where water and sewage charges add to your cost of operation. If water pollution is a concern.

- If you would like to minimize your maintenance requirements.

Advantage-D Systems

Advantage-D dry rotary vane vacuum systems utilize Becker’s oil-less rotary vane vacuum pumps, which use vanes made of carbon/resin composite material unique to Becker.

Advantage-X Systems

Advantage-X dry rotary vane vacuum systems are similar to our Advantage-D systems, but feature our long lasting vane design for an extended vane life of 20,000 hours.

VACUUM PUMPS

All pumps used on our systems are Becker Manufactured and individually tested at factory before shipping. Becker’s oil-free rotary vane vacuum pumps are 100% oil-less, dry positive displacement pumps. Additional specifications are:

- End vacuum up to 27”Hg (Model Dependent)

- Integrated 2-micron paper inlet filter

- Carbon dust separator and vacuum safety relief valves

- Liquid filled vacuum gauges installed at the pump

- Quick and simple maintenance procedures

- ST25-ST40 – Direct drive integrated motor

- ST60-ST250 – Single shaft direct drive through coupling

- IE3/NEMA PREMIUM efficiency motors

- TEFC Motors

- 208V/230V/460V/575V – 3-phase motor options

PLUMBING & RECEIVER

All vacuum pumps are plumbed to a manifold and connected to the air receiver. A check valve is installed at the pump inlet to prevent backflow in the system. Ball valves are installed for pump and receiver isolation. One point connection for vacuum plumbing is standard for all Becker systems. Optional manifold and one point connection for exhaust plumbing is available. All air receivers are ASME stamped to code and may have a mounted bypass and drain to allow for manual liquid removal.

CONTROL PANEL

NEMA type 3R, 4 & 12 enclosure with UL/CSA listing; mounted and prewired for simplex, duplex, or expandable controls. Panel also includes a 7” touchscreen LCD HMI unit to display system status. HMI provides access to basic system setup settings such as number of active pumps, vacuum high/low setpoints, and min/max run time. Live monitoring of each pump motor’s average amperage and amperage per phase is also available.

PLC control unit offers the following communication services:

- Ethernet/IP slave device

- Modbus TCP

- SMS/email notifications

- Web server (WebVisu)

Oil-Less Rotary Vane Central Vacuum Systems

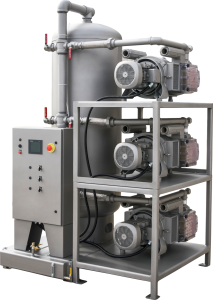

Tank-Mount Oil-Less Rotary Vane Vacuum Systems

Tank-mount oil-less rotary vane vacuum systems are cost effective systems, offering capabilities adequate for many facilities, while providing the basic functions of automatic operation and convenience provided by the programmable controller. They are compact in design due to the pump being mounted on top of the receiver. Becker’s oil-less rotary vane systems are available in simplex or duplex versions, and are available for industrial or medical/surgical use.

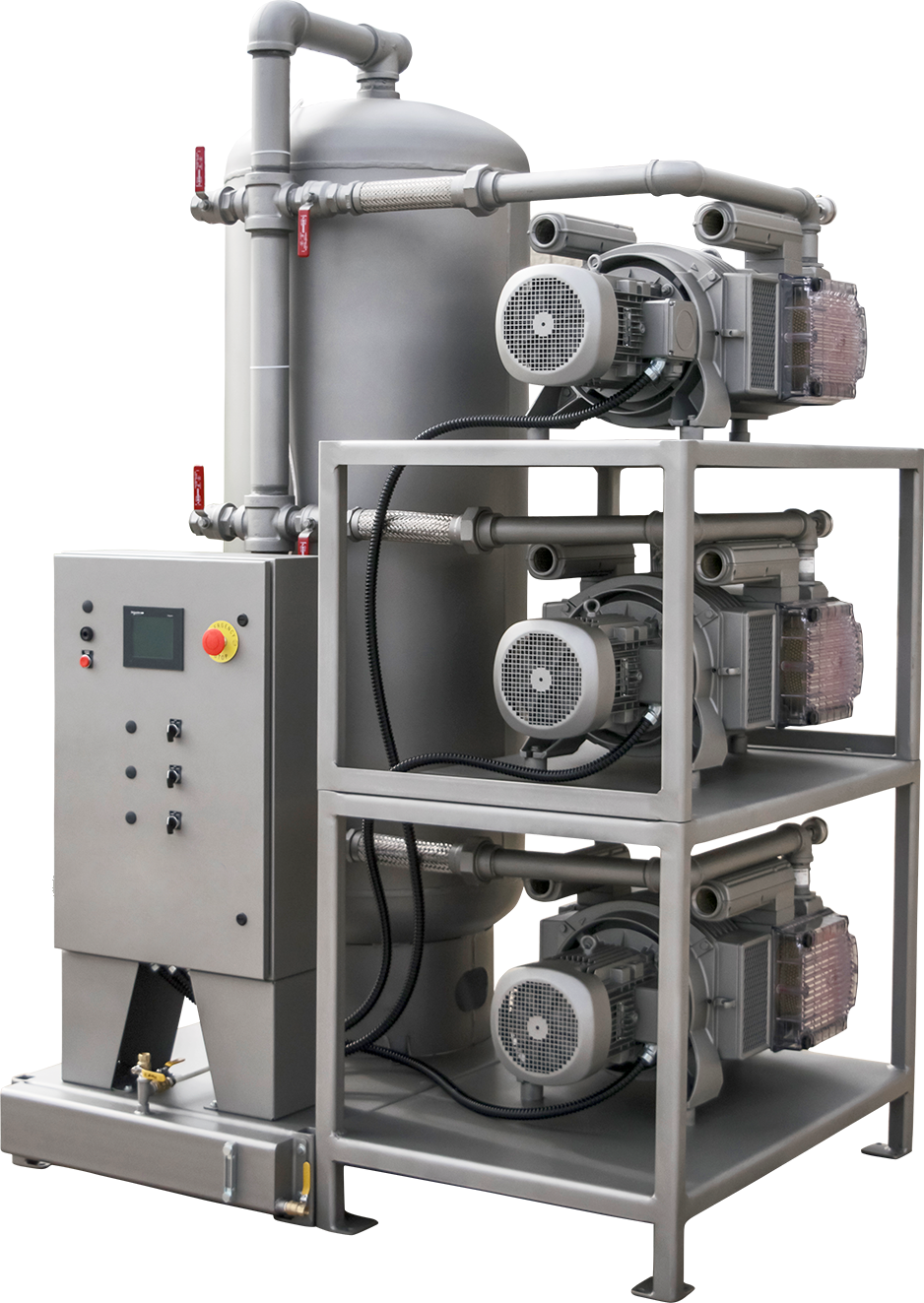

Expandable Oil-Less Rotary Vane Vacuum Systems

Expandable oil-less rotary vane vacuum systems utilize Becker’s dry rotary vane vacuum technology. Pumps, air receiver and control panel are mounted to modular skids to allow for future expansion. They are designed to be easily expandable from any smaller size option up to six pumps, and provide automatic operation and convenience, thanks to the programmable controller. Becker’s expandable dry rotary vane systems are available in triplex, quadruplex, and sextuplex versions, and are available for industrial or medical/surgical use.

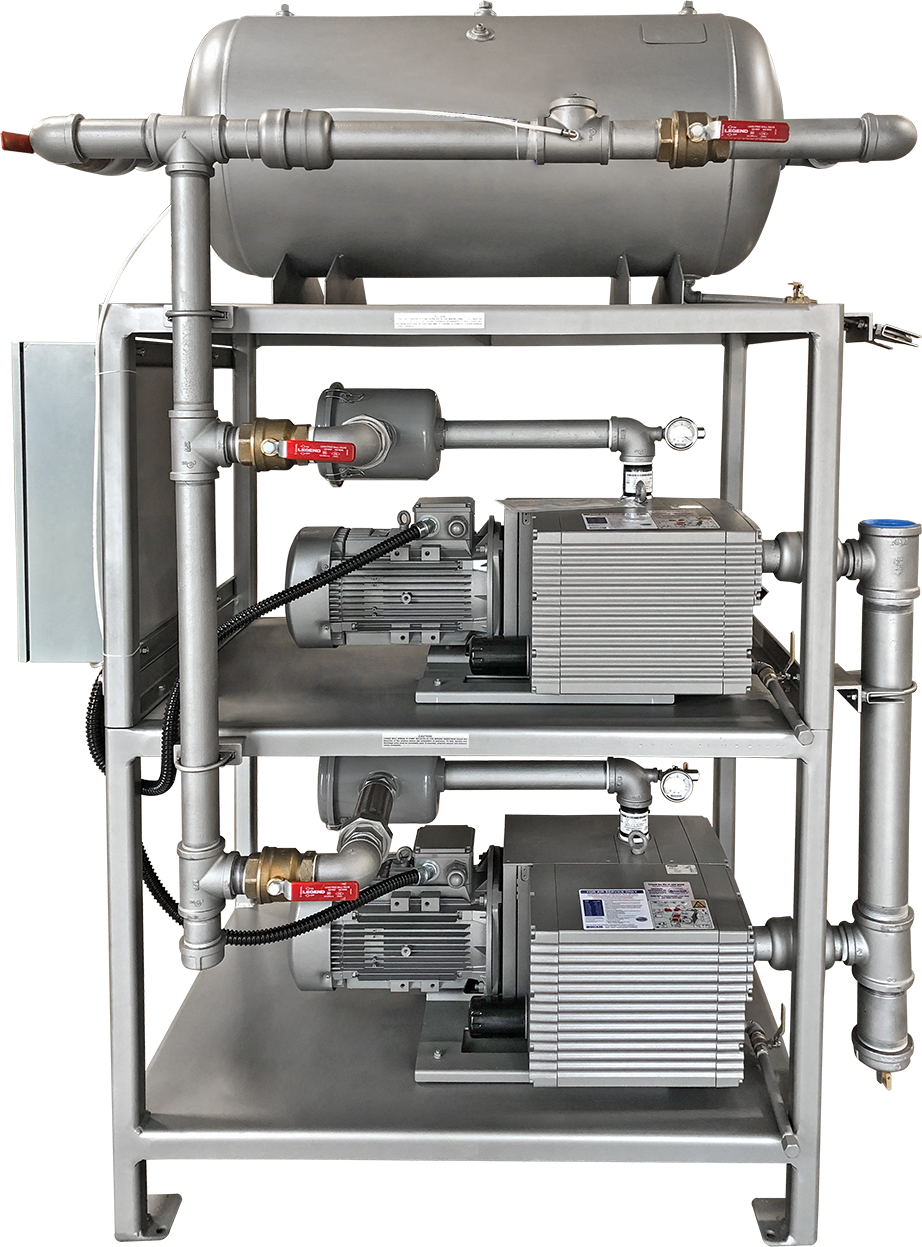

Space Saver Oil-Less Rotary Vane Vacuum Systems

Space saver dry rotary vane vacuum systems offer a compact footprint for installations where space is restricted. They are cost effective systems, offering capabilities adequate for many facilities, while providing the basic functions of automatic operation and convenience provided by the programmable controller. Becker’s oil-less rotary vane systems are available in a duplex version, and are available for industrial or medical/surgical use.

REQUEST INFORMATION

WE ARE PLEASED TO ASSIST YOU IN SERVICING YOUR BECKER PRODUCTS.

When can I expect to hear back?

Our goal is to respond to all care and employment inquiries within 24 hours of receipt. Our Becker Pumps Corporate offices are generally open Monday – Friday from 8am to 5pm EST time.