VACUUM PUMPS

Industrial Vacuum Pumps for All Applications

![]()

Becker designs and manufactures a variety of industrial vacuum pump technologies. From 0″ to 29.90″ Hg, primary pumps to booster pumps, positive displacement pumps to dynamic pumps, our vacuum pumps cover a wide range of operating pressures, principles, and technologies, including oil-less/dry and oil-lubricated rotary vane, oil-less/dry rotary screw, claw, and radial vacuum pumps, as well as regenerative blowers configured for vacuum applications.

Each type of vacuum pump has unique advantages in regard to vacuum level, flow rate, cost and maintenance requirements, but the basic outcome is the same, creating vacuum for a specific application. Becker vacuum pumps are built to withstand even the toughest industrial environments and operating conditions.

Regardless of operating pressure, pump type or technology, understanding the function of the pump is critical to the proper design and operation of any vacuum application. Our team has the experience needed to help find the perfect pump for your application, environment, and operation.

Industrial Vacuum Pumps

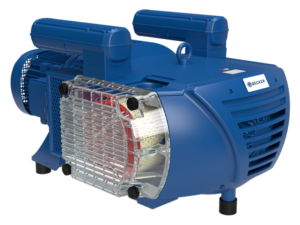

Rotary Vane Vacuum Pumps

The robustly constructed rotary vane pumps are also suitable for higher pressure differences in vacuum applications. An eccentrically mounted rotor with slots rotates in a cylindrical housing and the precisely fitting sliding vanes move in the slots and separate the individual working chambers

Dry Screw Vacuum Pumps

Thanks to the direct drive via an integrated frequency inverter, a drive gear is no longer required. The rotors with screw profile rotate in opposite directions and contactless. The working chamber of the machines is 100% oil-free. The integrated speed control enables energy-optimized operation of the devices.

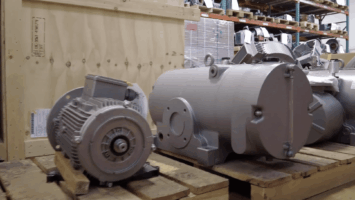

Roots Booster Pumps

Roots booster vacuum pumps, or roots vacuum pumps are dry positive displacement pumps. They operate using the Roots operating principle, a working principle similar to rotary vane pumps. These pumps are the ideal solution when large pumping speeds are required.

Radial Vacuum Pumps

Radial blowers are designed for high delivery volumes. The volume flow can be precisely adapted to customer requirements using the frequency inverter integrated on the motor. Radial blowers contain a fast and contact less rotating impeller, making them wear and maintenance free.

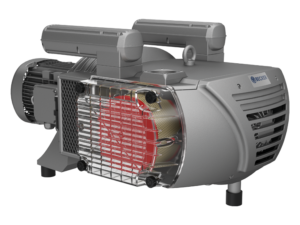

Claw Vacuum Pumps

Claw vacuum pumps are 100% free of oil and contact during operation. To achieve this, the claw-like rotors rotate within the compression chamber in opposite directions without touching one another of the housing. The claw technology ensures a high degree of efficiency and low energy consumption.

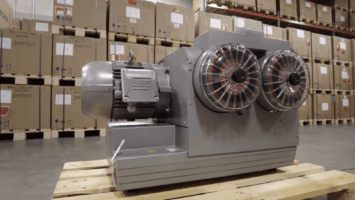

Regenerative Blowers

Regenerative blowers generate suction for a wide variety of industrial applications. They contain a contact less, fast rotating impeller and are therefore wear and maintenance free. On both sides of the impeller there are two ring-shaped separate side channels along with the housing.

Recent Blog Posts

How to Choose a Vacuum Pump

Choosing the right vacuum pump can ensure that your operations will be the most cost and energy-efficient, with the least maintenance and minimal downtime. In this article, the experts at Becker offer their advice on how to make the optimal selection for your application – whether it be secondary packaging,...

Quality vs. Upfront Cost: Comparing Vacuum Pumps

It’s common for purchasing managers to choose a vacuum pump at or near the lowest price available. However, the quality of the pump significantly impacts the cost and performance of the pump over its lifespan. In this article, we dive into the many factors affecting the lifetime cost of high-quality...

Case Study: Global Vision, Custom Delivery for a Packaging Equipment OEM

When a leading supplier of processing and packaging equipment to the pharmaceutical and food industries needed a global partner to help deliver a fully integrated solution to clients around the world, they turned to Becker. Concerned that their existing supplier lacked the global mindset needed to deliver tailor-made solutions for...

How Much Does a Regenerative Blower Cost?

Whether you’re an OEM pricing a regenerative blower for your product or an operations manager in need of a quick replacement for a pump that has failed prematurely, one of the first questions you may ask is, “what’s it going to cost?” It isn’t easy to estimate the cost of...

8 Factors to Consider When Selecting a Regenerative Blower

Whether you are buying a regenerative blower for a manufacturing, environmental, or secondary packaging application, regen technology from Becker offers a moderately priced, reliable unit that can last a decade or more with minimal maintenance. Several different types of blowers could meet your application’s pressure and flow specifications. Regenerative blowers,...

REQUEST INFORMATION

WE ARE PLEASED TO ASSIST YOU IN SERVICING YOUR BECKER PRODUCTS.

When can I expect to hear back?

Our goal is to respond to all care and employment inquiries within 24 hours of receipt. Our Becker Pumps Corporate offices are generally open Monday – Friday from 8am to 5pm EST time.