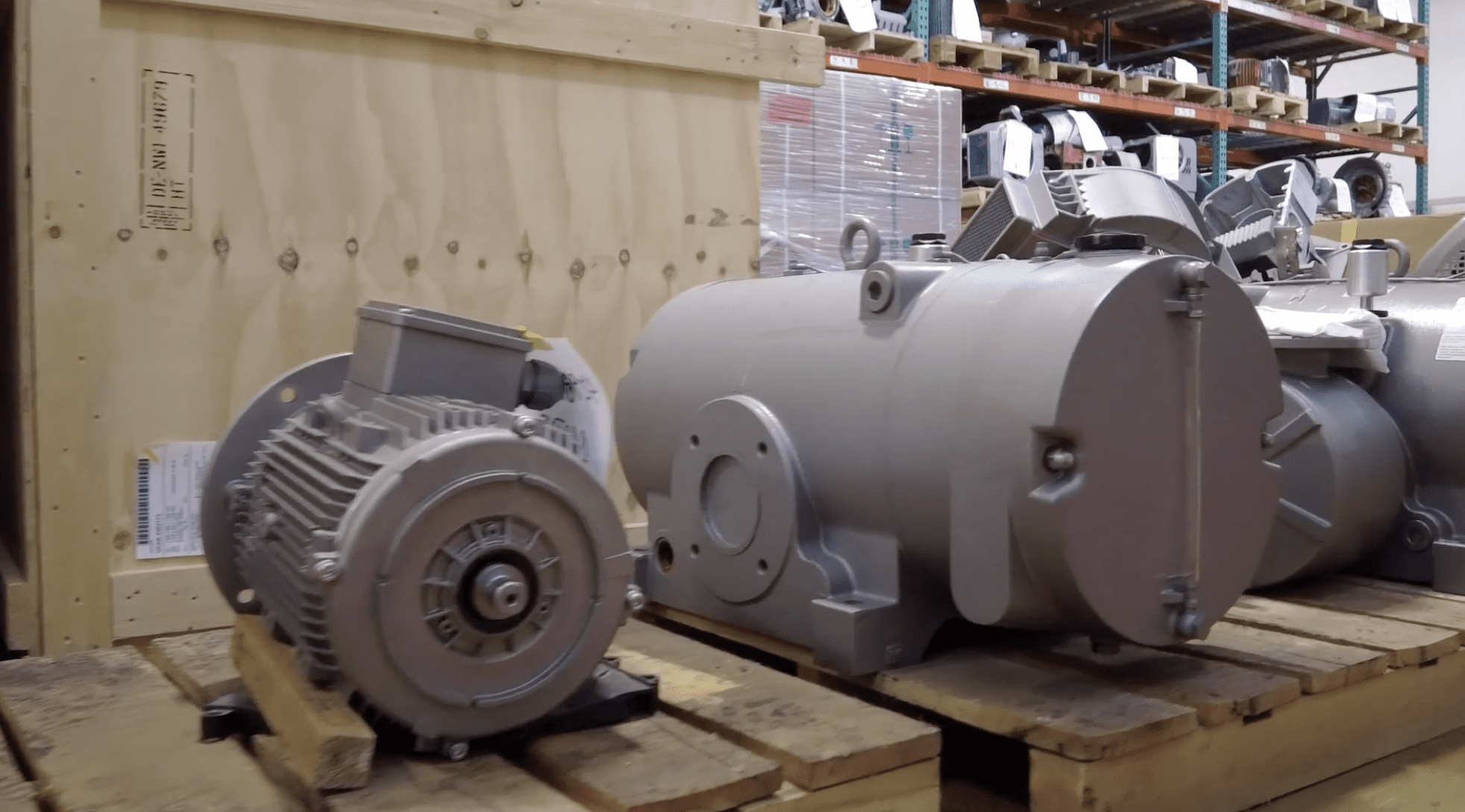

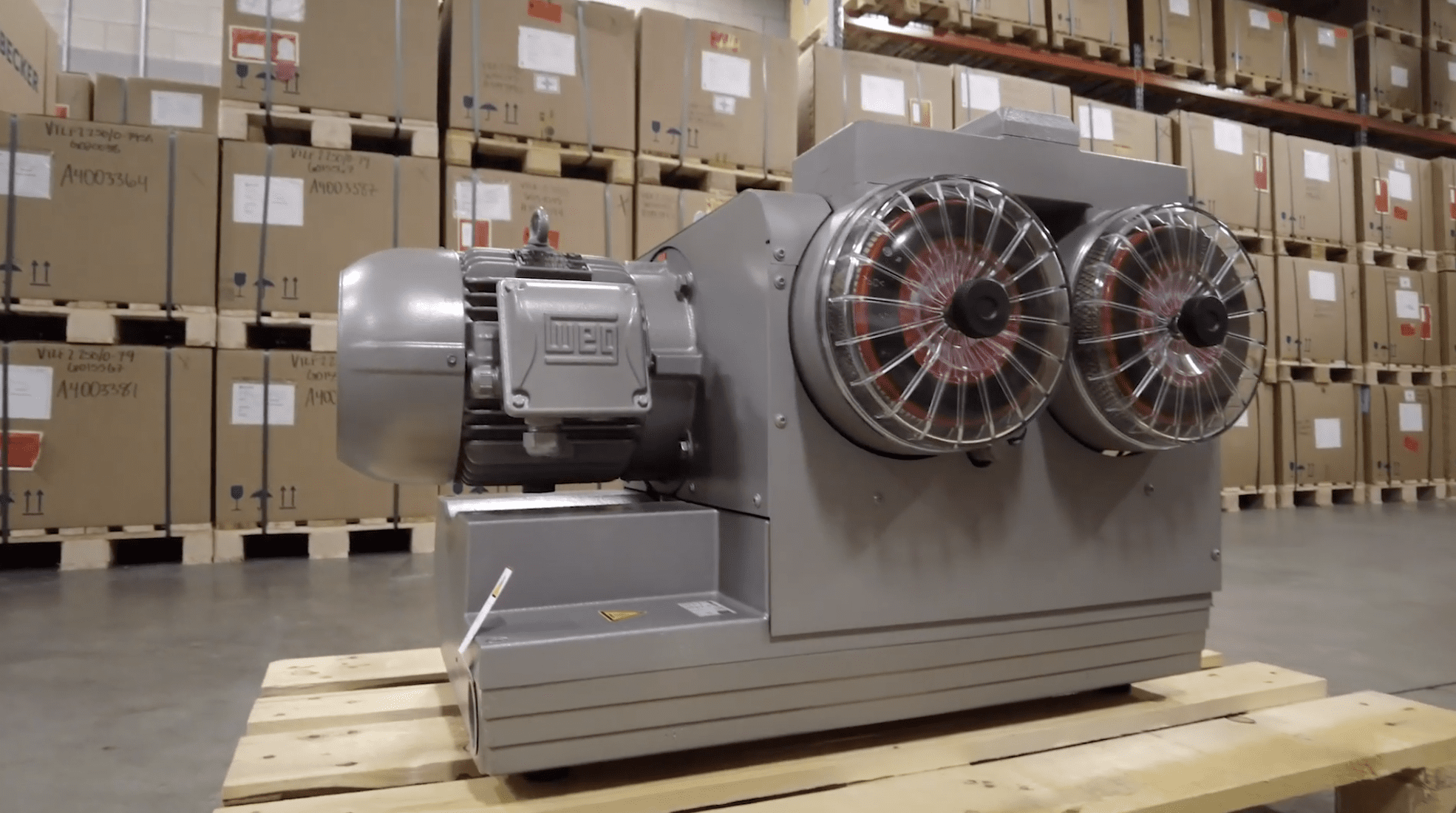

U Series

Oil Lubricated Rotary Vane Vacuum Pumps

The robustly constructed rotary vane pumps are suitable for higher pressure differences in vacuum applications. An eccentrically mounted rotor with slots rotates in a cylindrical housing and the precisely fitting sliding vanes move in the slots and separate the individual working chambers. Compared to dry-running rotary vane pumps, oil-lubricated pumps additionally seal the working chambers with the oil that is also transported. The pumps are thus able to generate a fine vacuum and are therefore suitable for applications that require a high vacuum.

Each U Series pump comes standard with:

- Energy efficient, low electricity consumption

- High efficiency oil separator element

- Oil tank with dual stage oil separation

- Gas ballast valves available

Features

- Energy efficient, low electricity consumption

- High efficiency oil separator element

- Oil tank with dual stage oil separation

- Semi or full synthetic oil

- Gas ballast valves available

- Single shaft direct drive

- Robust and long-lasting

Benefits

- Low operation and maintenance costs

- Cool and quiet operation

- Small footprint for space savings

- Straightforward construction for fast and easy service on-site to reduce downtime

- High water vapor tolerance

- Best cold start performance

- Compact design for easy integration

Product Information / Specifications

| Model | Open Flow SCFM | Maximum Vacuum | Horsepower | Data Sheet |

Operating Manual |

Spare Parts List |

|---|---|---|---|---|---|---|

| U 4.20 | 12 | 1 Torr | 1 | view | view | view |

| U 4.40 | 28 | 0.375 Torr | 2.4 | view | view | view |

| U 5.65 (XL K) | 46 | 0.375 Torr | 2.0-2.4 | view | view | view |

| U 5.71 | 49 | 0.075 Torr | 2.4 | view | view | view |

| U 5.101 | 71 | 0.075 Torr | 3.5 | view | view | view |

| U 5.166 | 116 | 0.075 Torr | 6.4 | view | view | view |

| U 5.201 | 141 | 0.075 Torr | 8.9 | view | view | view |

| U 5.301 | 211 | 0.075 Torr | 12.1 | view | view | view |

| U 4.400 F | 299 | 0.5 Torr | 17.7 | view | view | view |

| U 4.400 SA/K | 299 | 2 Torr | 17.7 | view | view | view |

| U 4.630 F | 430 | 0.5 Torr | 24.1 | view | view | view |

| U 4.630 SA/K | 430 | 2 Torr | 24.1 | view | view | view |

APPLICATION AND MARKET USES

The U Series vacuum pumps are ideally suited for the vacuum packaging of food. They can be used across a wide range of applications from vacuum chamber machines, form-fill-seal machines and tray sealer. Their straightforward construction with single shaft direct drive makes for a robust, long-life rotary vane pump with high reliability even in the most demanding applications.

BY APPLICATION

-

Degassing

Vacuum pumps are the preferred solution for removing gases, air, moisture, and vapor from processed materials like plastics, ceramic, and pasta to improve the finished product quality. -

Evacuation

From food processing and packaging, to thermoforming and manufacturing, the removal of air or gas from a given space is one of the most wide ranging applications of vacuum pumps and systems. -

Extracting

Vacuum pumps and blowers are used for a wide range of applications that require the removal of fluids, waste, air, as well as various other materials. -

Vacuum Fixing

Vacuum pumps and vacuum systems from Becker are the ideal solution for holding goods and components in place during production, processing, and packaging.

BY MARKET

-

CNC Routing - Woodworking Industry

Vacuum pumps from Becker, provide the strong vacuum hold down that is imperative for keeping parts in place and reducing scrap. -

Composite / RTM / LRTM Manufacturing

Autoclaves, vacuum layup, and Composite/RTM/LRTM manufacturing, large and small, are handled easily and efficiently with Becker pumps and systems. -

Energy

Becker vacuum pumps and blowers follow the trend to new technologies and are an important and efficient component of stationary fuel cells, and battery production, among others. -

General Mechanical Engineering

Becker provides customized vacuum pump and compressor solutions for numerous mechanical engineering applications across the world, such as conveying, transporting, fixing, lifting, handling, drying, cooling and many more. -

Laser Industry

Blower components are assembled, following a multi-stage cleaning process – under clean room conditions, and deployed as extraction or recirculation blowers for noble gases like helium or to convey inert gases, for example. -

Maple Sugar Extraction

Becker vacuum pumps and accessories are designed to be sturdy and durable with low maintenance and operating costs, and are perfectly suited for use in maple sugar extraction. -

Medical Industry

Our highly reliable vacuum pumps are found in many central medical/surgical vacuum systems and medical devices. -

Primary Packaging and Food Processing

Whether you have an inline tray sealer, chamber machine, rotary chamber machine, tumbler or massager our robust vacuum pumps keep your machine running. -

Plastics Industry

From the production of new plastic components to the resource-friendly recycling of PET – vacuum pumps/systems and compressors from Becker are involved in the process. -

Thermoforming

From clamshells, to blisters and trays we offer several vacuum pump technologies to meet your individual needs.

Information & Resources

Our Industrial Vacuum Pump Technical Guide

Becker has designed a comprehensive handbook for the use of our distributors and customers as an aid in the designing of applications involving vacuum and low pressure compressed air. Just some of what you’ll find in the complete handbook includes: Similarity of units CFM vs. SCFM vs. ACFM Motor cycling...

How to Determine the Cost of a Vacuum Pump

For manufacturers and resellers, calculating the true cost of a vacuum pump before purchasing is often a challenge. We look at the real factors that affect what you’ll pay for a new vacuum solution.

Tips for Custom Vacuum Pump Design

For many applications, a custom vacuum pump design is the best way to get a fit-for-purpose solution that improves efficiency and doesn’t compromise on features. However, the customization is only worthwhile if it meets your specific needs.

REQUEST INFORMATION

WE ARE PLEASED TO ASSIST YOU IN SERVICING YOUR BECKER PRODUCTS.

When can I expect to hear back?

Our goal is to respond to all care and employment inquiries within 24 hours of receipt. Our Becker Pumps Corporate offices are generally open Monday – Friday from 8am to 5pm EST time.