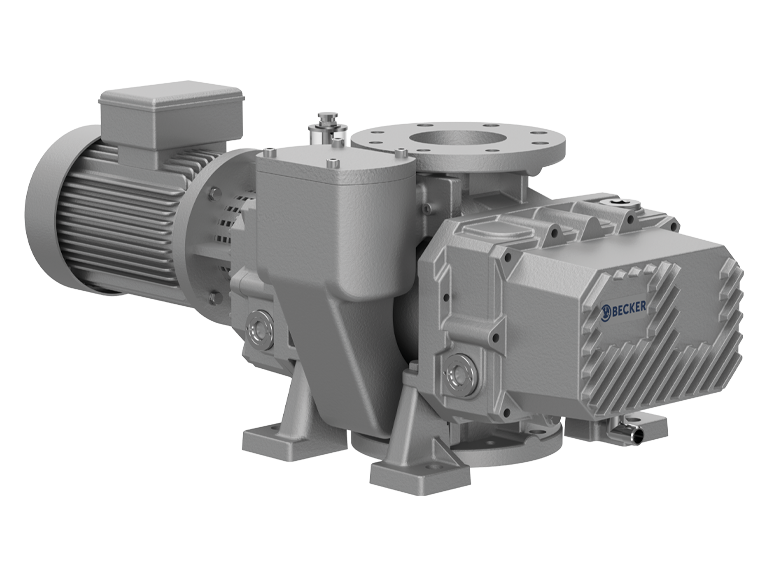

RBP Series

Oil-Less Roots Booster Vacuum Pump

Becker RBP Series vacuum pumps are high vacuum, dry booster pumps that operate using the Roots operating principle. In combination with an oil-lubricated rotary vane pump, Roots booster pumps, or Roots blowers are often used in pumping stations to achieve a very high-volume flow with a deep final vacuum. No oil to change and only minimal maintenance is required.

Each RBP Series pump comes standard with:

- Bypass valve

- Built-in inlet filter

- Vacuum regulating valve

- Vibration isolators

- Discharge silencers

Features

- 100% dry operation

- Air-cooled

- Compact design

- Variety of motors available

- Single shaft direct drive

- Continuous duty rated

Benefits

- Low operation and maintenance costs

- Cool operation

- No cycling times

- Quiet operation – no silencer enclosures necessary

- Small footprint for space savings

- Straightforward construction for fast and easy service on-site to reduce downtime

Product Information / Specifications

APPLICATION AND MARKET USES

The RBP Series’ straightforward construction makes for a robust, long-life displacement pump with low operation and maintenance costs, perfectly suited for applications requiring high pumping speeds.

BY APPLICATION

-

Evacuation

From food processing and packaging, to thermoforming and manufacturing, the removal of air or gas from a given space is one of the most wide ranging applications of vacuum pumps and systems.

BY MARKET

-

Primary Packaging and Food Processing

Whether you have an inline tray sealer, chamber machine, rotary chamber machine, tumbler or massager our robust vacuum pumps keep your machine running.

Information & Resources

Case Study: A Sugarhouse Boosts Efficiency & Saves Money

This case study focuses on Ben & Judy’s Sugarhouse, a renowned sugar business in New York that creates various maple products. When Ben & Judy’s Sugarhouse faced a difficult challenge, Ben Benjamin reached out to a trusted advisor in the industry and ultimately contacted Becker Pumps for a permanent solution. ...

Symptoms of a Bad Vacuum Pump

Vacuum pumps provide mission-critical pressure relief in a wide range of situations where an interruption to supply can have serious consequences. From medical facilities and agriculture to uninterruptible manufacturing processes, unplanned pressure disruptions can lead to unsafe conditions and trigger costly shutdowns and production losses. In situations like these, it’s...

Deeper Vacuum Creates Leaks in Tubing: Myth vs. Reality

Maple syrup production is a time-honored tradition that relies on meticulous tapping of maple trees to extract their precious sap. In recent years, the use of deep vacuum systems for maple extraction has sparked debate, with some concerns that these systems cause micro leaks in tree taps. However, it’s crucial...

How to Use a Vacuum Pump for Robotic Material Handling

Whether it’s electronics, logistics, packaging & food processing, printing & paper, construction, or another production process, robotic material handling can be the fastest, most accurate, and most efficient method of picking and placing materials. Every manufacturing process has its requirements for handling materials. In addition to selecting industrial robots and...

How to Choose a Vacuum Pump

Choosing the right vacuum pump can ensure that your operations will be the most cost and energy-efficient, with the least maintenance and minimal downtime. In this article, the experts at Becker offer their advice on how to make the optimal selection for your application – whether it be secondary packaging,...

What to Do if Your Vacuum Pump is Making a Loud Noise

Your vacuum pump may have been running smoothly for some time, all the while producing a continuous humming sound. But what does it mean when the noise level rises? Should you be concerned? In this post, we examine the many possible reasons for loud noises or a rattling sound coming...

REQUEST INFORMATION

WE ARE PLEASED TO ASSIST YOU IN SERVICING YOUR BECKER PRODUCTS.

When can I expect to hear back?

Our goal is to respond to all care and employment inquiries within 24 hours of receipt. Our Becker Pumps Corporate offices are generally open Monday – Friday from 8am to 5pm EST time.