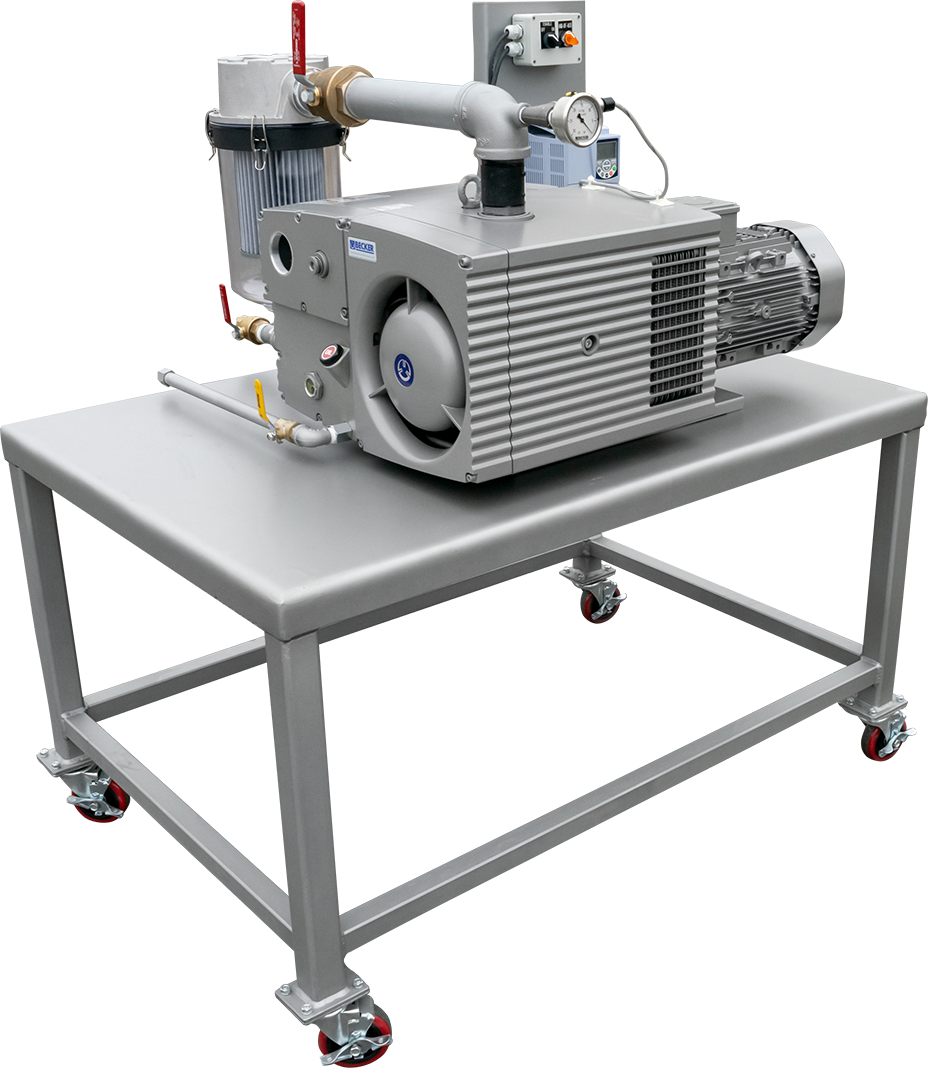

Advantage M - Oil-Lubricated Rotary Vane Maple Vacuum Systems

The Advantage M – Oil-Lubricated Maple System is a specialized system designed for efficient maple sugar extraction, for up to 21,100 taps (depending on terrain and setup). It features one Becker brand oil-flooded rotary vane vacuum pump with integrated filtration and frequency control. Pump and control components are mounted to mobile stand. VFD and vacuum transducer provide two control options for manual or automatic control.

Click here to view complete Advantage M – Lubricated Maple System specifications.

Features

- Oil sight glass for visual inspection

- Clear canister filter with manual drain to protect pump against liquid ingestion

- VFD and vacuum transducer provide two control options: Manual Control and Automatic Control

Benefits

- End vacuum of 29″ Hg+ provides increased yield

- Increased pump lifespan thanks to gas ballast

- Manual control option allows for control based on user set frequency

- Automatic control option controls system based on feedback from vacuum transducer to maintain a constant vacuum level

Product Information / Specifications

APPLICATION AND MARKET USES

Becker has been building specialized vacuum systems in the US for over 3 decades. The Advantage M – Maple System is the ideal solution for the maple syrup production and maple sugar extraction industries, as well as others. Click on your market or application below to learn how Becker’s vacuum systems can help your business or application.

BY APPLICATION

-

Extracting

Vacuum pumps and blowers are used for a wide range of applications that require the removal of fluids, waste, air, as well as various other materials.

BY MARKET

-

Maple Sugar Extraction

Becker vacuum pumps and accessories are designed to be sturdy and durable with low maintenance and operating costs, and are perfectly suited for use in maple sugar extraction.

Information & Resources

How to Use a Vacuum Pump for Robotic Material Handling

Whether it’s electronics, logistics, packaging & food processing, printing & paper, construction, or another production process, robotic material handling can be the fastest, most accurate, and most efficient method of picking and placing materials. Every manufacturing process has its requirements for handling materials. In addition to selecting industrial robots and...

How to Choose a Vacuum Pump

Choosing the right vacuum pump can ensure that your operations will be the most cost and energy-efficient, with the least maintenance and minimal downtime. In this article, the experts at Becker offer their advice on how to make the optimal selection for your application – whether it be secondary packaging,...

What to Do if Your Vacuum Pump is Making a Loud Noise

Your vacuum pump may have been running smoothly for some time, all the while producing a continuous humming sound. But what does it mean when the noise level rises? Should you be concerned? In this post, we examine the many possible reasons for loud noises or a rattling sound coming...

Quality vs. Upfront Cost: Comparing Vacuum Pumps

It’s common for purchasing managers to choose a vacuum pump at or near the lowest price available. However, the quality of the pump significantly impacts the cost and performance of the pump over its lifespan. In this article, we dive into the many factors affecting the lifetime cost of high-quality...

5 Common Problems With Vacuum Pumps

With so many types and brands of industrial vacuum pumps on the market today, a wide range of issues can arise that can negatively impact your business. In this post, we examine the five most common problem areas and how to resolve them – whether repairing or replacing the pumps...

The Most Valuable Feature of High-Quality Vacuum Pumps

While you expect most quality vacuum pumps to offer performance, reliability, and ease of use right out of the box, you won’t find the most valuable feature of leading brand pump equipment listed on a spec sheet. That’s because only the leading vacuum pump manufacturers deliver superior post-sale technical support...

REQUEST INFORMATION

WE ARE PLEASED TO ASSIST YOU IN SERVICING YOUR BECKER PRODUCTS.

When can I expect to hear back?

Our goal is to respond to all care and employment inquiries within 24 hours of receipt. Our Becker Pumps Corporate offices are generally open Monday – Friday from 8am to 5pm EST time.